The Rise of UV Encapsulation: Key Considerations for Choosing the Right Supplier

UV encapsulation is a critical technology in various industries, from electronics to packaging. It involves using ultraviolet (UV) light to cure or harden coatings, adhesives, and inks. This process enhances the durability and functionality of products by creating a protective layer. As industries increasingly rely on UV encapsulation for its efficiency and effectiveness, choosing the right supplier becomes crucial. This article delves into the significance of UV encapsulation, the factors to consider when selecting a supplier, and the leading suppliers in the market.

What is UV Encapsulation?

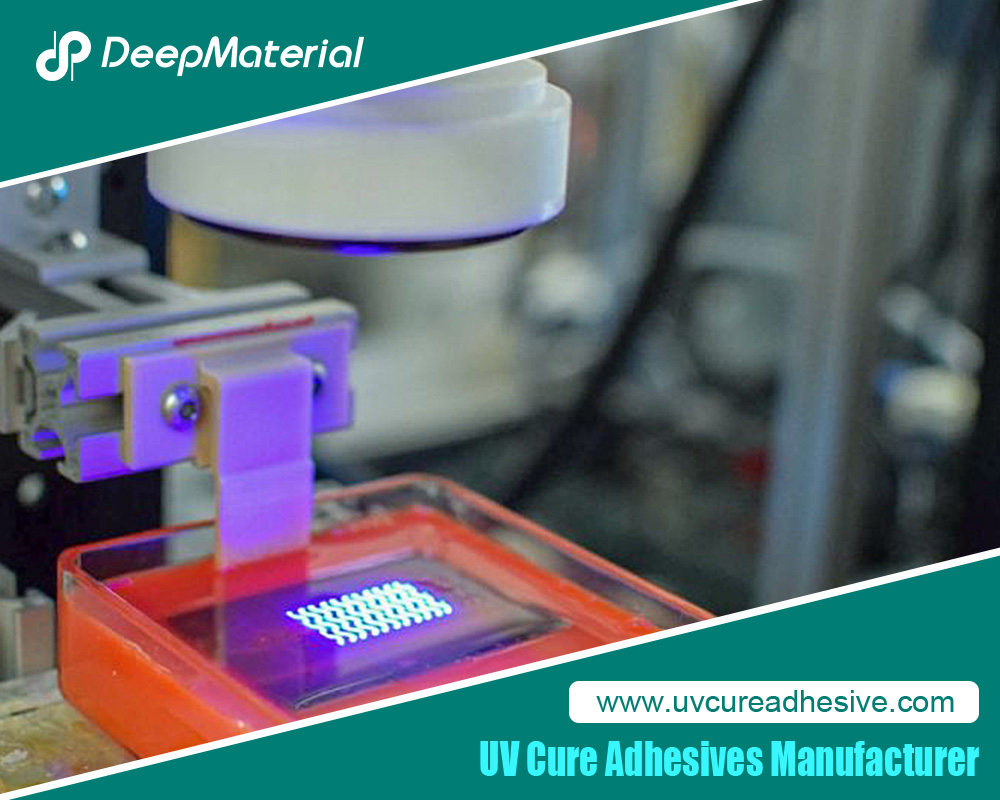

Definition and Process

UV encapsulation refers to applying a UV-curable coating or adhesive to a substrate, which is then exposed to ultraviolet light to cure or harden the material. This method offers several advantages, including rapid curing times, reduced energy consumption, and improved environmental safety compared to traditional curing methods. The UV light initiates a photochemical reaction that converts the liquid coating into a solid, creating a durable and protective layer.

Applications of UV Encapsulation

UV encapsulation is widely used in various applications, including:

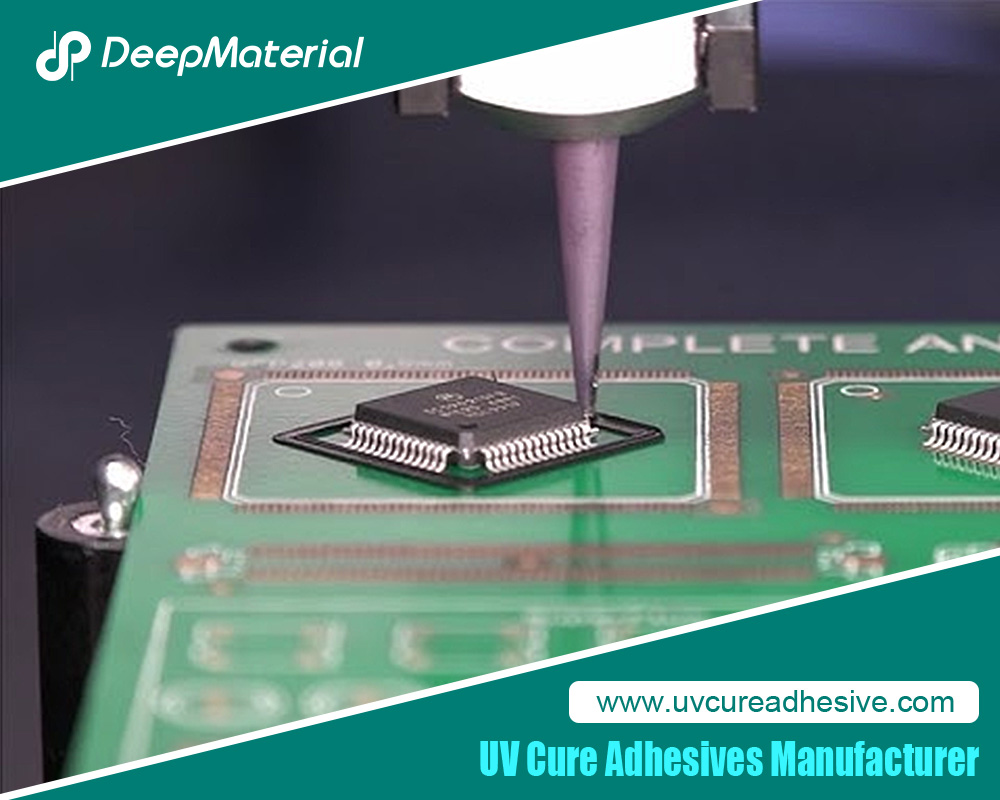

- Electronics: Protecting sensitive electronic components from moisture, dust, and physical damage.

- Packaging: Enhancing the durability and appearance of packaging materials.

- Automotive: Providing a protective layer on automotive parts to resist wear and tear.

- Medical Devices: Ensuring the safety and longevity of medical equipment and devices.

- Graphics and Printing: Improving the quality and longevity of printed materials.

Factors to Consider When Choosing a UV Encapsulation Supplier

Quality and Reliability

When selecting a UV encapsulation supplier, the quality and reliability of their products are paramount. High-quality encapsulation materials should offer excellent adhesion, durability, and resistance to environmental factors. Reliability in product performance and consistency are crucial to avoiding defects and ensuring the longevity of encapsulated products.

Quality Assurance

A reputable supplier should have robust quality assurance processes in place. This includes rigorous testing of their UV encapsulation materials to meet industry standards and certifications. Ask potential suppliers about their quality control procedures and any relevant certifications such as ISO 9001.

Technical Expertise

Another critical factor is the technical expertise of the supplier’s team. A knowledgeable supplier can provide valuable insights into selecting the right UV encapsulation solutions for your specific needs. They should also offer support in terms of application techniques, curing parameters, and troubleshooting.

Customization and Support

Choose a supplier that offers customization options to meet your unique requirements. This includes tailoring the encapsulation material to your specific application and providing technical support to address any challenges that may arise during the application process.

Product Range and Innovation

A diverse product range is essential to cater to different applications and industries. Look for suppliers that offer a variety of UV encapsulation products, including coatings, adhesives, and inks, to ensure you can find a solution that fits your needs.

Innovation

Innovation in UV encapsulation technology is crucial for staying ahead in the market. Suppliers that invest in research and development can offer advanced products with improved performance and new features. Please inquire about the supplier’s commitment to innovation and track record in introducing new technologies.

Cost and Value

Cost is a significant consideration, but it should be weighed against the value offered by the supplier. While lower-priced options may seem attractive, they may only sometimes provide the best performance or durability. Evaluate the total cost of ownership, including product lifespan, maintenance requirements, and potential cost savings from reduced application times or energy consumption.

Pricing Transparency

Ensure that the supplier provides transparent pricing with no hidden costs. Understand the pricing structure, including any additional charges for customization, technical support, or shipping.

Customer Reviews and Reputation

Researching customer reviews and the supplier’s reputation can provide valuable insights into their reliability and service quality. Look for feedback from other customers in your industry to gauge the supplier’s performance and customer satisfaction.

References and Case Studies

Ask the supplier for references or case studies demonstrating their experience and success in providing UV encapsulation solutions for similar applications. This can help validate their claims and provide reassurance about their capabilities.

Environmental Considerations

Environmental sustainability is becoming increasingly important in all industries. Choose a UV encapsulation supplier that prioritizes environmentally friendly practices, such as using low-VOC (volatile organic compounds) materials and implementing waste reduction measures.

Compliance with Regulations

Ensure that the supplier’s products comply with relevant environmental regulations and standards. This includes adherence to restrictions on hazardous substances and proper disposal practices.

Leading UV Encapsulation Suppliers

DSM Neoresins

DSM Neoresins is a prominent player in the UV encapsulation market and is known for its high-performance resins and coatings. With a strong focus on innovation and sustainability, DSM Neoresins offers a wide range of UV-curable materials for various applications, including electronics and packaging.

Sartomer (a part of Arkema)

Sartomer, a division of Arkema, is a leading supplier of UV-curable resins and photoinitiators. Its products are widely used in coatings, adhesives, and inks. Sartomer is known for its commitment to innovation and quality and provides advanced solutions for UV encapsulation.

Hexion

Hexion is a global supplier of specialty chemicals, including UV-curable coatings and adhesives. Their products are designed for high-performance applications and offer excellent adhesion, durability, and environmental resistance. Hexion’s focus on research and development ensures it stays at the forefront of UV encapsulation technology.

PPG Industries

PPG Industries is a significant player in the coatings industry, including UV-curable coatings. Their extensive product range includes automotive, industrial, and consumer applications solutions. PPG’s commitment to quality and innovation makes them a reliable choice for UV encapsulation needs.

BASF

BASF is a global leader in chemical products, including UV-curable resins and coatings. Their UV encapsulation solutions are known for their high performance and environmental compatibility. BASF’s expertise in materials science and commitment to sustainability make them a top choice for various industries.

Conclusion

UV encapsulation plays a vital role in enhancing the durability and performance of products across various industries. Choosing the right supplier is crucial to ensuring the quality and effectiveness of UV encapsulation solutions. You can make an informed decision that meets your needs by considering quality, technical expertise, product range, cost, customer reviews, and environmental considerations.

Leading suppliers like DSM Neoresins, Sartomer, Hexion, PPG Industries, and BASF offer a range of high-performance UV encapsulation products and support services. Evaluating these factors and researching potential suppliers will help you select a reliable partner to provide adequate UV encapsulation solutions for your applications.

In a rapidly evolving industry, staying updated with the latest technologies and innovations in UV encapsulation will enable you to make the best choices for your business.

For more about choosing the rise of UV encapsulation: key considerations for choosing the right supplier, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.