The Power of Magnetic Iron Bonding Adhesive: A Comprehensive Guide

Finding effective and reliable adhesives has led to remarkable modern manufacturing and construction innovations. Magnetic Iron Bonding Adhesive has emerged as a transformative solution for various applications. This adhesive combines the strengths of magnetic properties with robust bonding capabilities, making it ideal for industries ranging from automotive to electronics. This article will explore the science behind Magnetic Iron Bonding Adhesive, its applications, benefits, and considerations for use.

What is Magnetic Iron Bonding Adhesive?

Magnetic Iron Bonding Adhesive is a specialized adhesive incorporating magnetic iron particles into its formulation. This unique combination allows it to bond materials while providing magnetic properties, making it suitable for various applications.

Key Components

- Iron Particles:Provide the magnetic properties.

- Polymer Matrix: Acts as the bonding agent, ensuring durability and adhesion.

- Additives:Enhance performance characteristics such as temperature resistance and curing speed.

How Does Magnetic Iron Bonding Adhesive Work?

The functionality of Magnetic Iron Bonding Adhesive is rooted in its dual properties: adhesion and magnetism.

Adhesion Process

- Surface Preparation:Surfaces must be clean and dry to ensure optimal bonding.

- Application:The adhesive is applied evenly across the surfaces to be bonded.

- Curing:Depending on the formulation, the adhesive cures at room temperature or heat.

- Bond Formation:As the adhesive cures, it creates a strong bond that can withstand stress and strain.

Magnetic Properties

- Magnetic Activation:Once cured, the adhesive’s magnetic properties can be activated, allowing magnetic components or materials to be attached.

- Reusability:Some formulations allow for the repositioning bonded parts without permanent damage.

Applications of Magnetic Iron Bonding Adhesive

The versatility of Magnetic Iron Bonding Adhesive opens the door to numerous applications across different industries.

1. Automotive Industry

- Component Assembly:Used for bonding parts such as sensors and brackets.

- Magnetic Attachments:Enables easy attachment and detachment of components for maintenance.

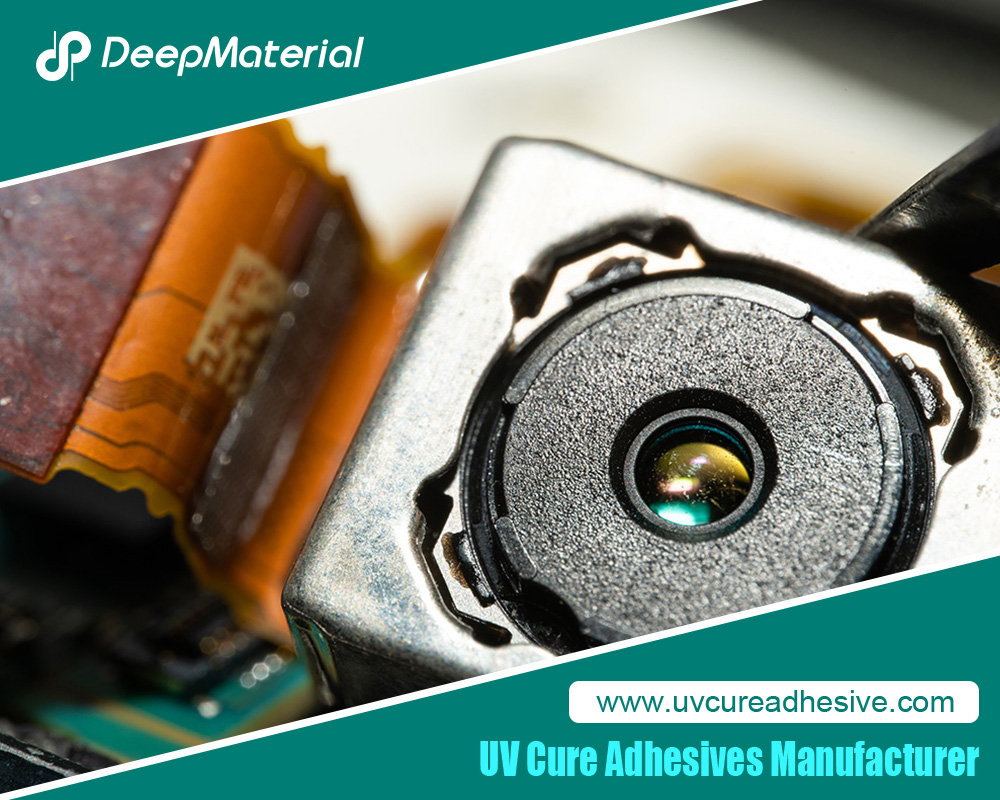

2. Electronics

- Device Enclosures:Provides a secure bond for electronic components while offering magnetic connectivity for accessories.

- Sensor Mounting:Ideal for mounting sensors that require precise alignment.

3. Furniture and Decor

- Modular Furniture: Allows for easy assembly and disassembly of furniture pieces.

- Decorative Elements:Attaches decorative elements that can be repositioned as needed.

4. Medical Devices

- Device Assembly:Facilitates the assembly of complex medical devices where magnetic alignment is crucial.

- Magnetic Interfaces:Used in devices that require quick attachment and detachment.

Benefits of Magnetic Iron Bonding Adhesive

The use of Magnetic Iron Bonding Adhesive offers several advantages:

Enhanced Bond Strength

- Durability:Forms solid and long-lasting bonds that can withstand stress.

- Temperature Resistance:Many formulations are designed to withstand high temperatures.

Magnetic Features

- Versatility: The ability to bond and detach components easily.

- Customization: Enables creative solutions for product design.

Time and Cost Efficiency

- Quick Application: Reduces assembly time in manufacturing processes.

- Reduced Waste: Allows for reusability and repositioning, minimizing material waste.

Considerations When Using Magnetic Iron Bonding Adhesive

While the benefits are substantial, there are essential considerations to consider.

Surface Compatibility

- Material Types:Not all materials bond well with magnetic iron adhesives. Test compatibility before completing the application.

- Surface Treatment:Some surfaces may require unique treatments to enhance adhesion.

- Environmental Factors

- Temperature Limits:Ensure the adhesive is suitable for the temperature range of the application.

- Moisture Sensitivity:Consider the effects of humidity and moisture on bond strength.

Application Techniques

- Proper Mixing:Ensure the adhesive components are mixed according to manufacturer instructions.

- Curing Time:Allow adequate curing time for optimal bond strength.

The Future of Magnetic Iron Bonding Adhesive in Industry

As industries continue to evolve and adapt to new technologies, Magnetic Iron Bonding Adhesive is poised to play a critical role in shaping the future of manufacturing and assembly. The unique combination of adhesive and magnetic properties offers innovative solutions that enhance productivity, efficiency, and design flexibility.

Emerging Trends and Innovations

Smart Adhesives:

- Development of adhesives that respond to environmental changes, such as temperature or moisture.

- Potential for self-healing properties that can repair minor damages.

Sustainability Focus:

- There is an increasing demand for eco-friendly formulations that minimize environmental impact.

- Use of recyclable materials in adhesive production.

Integration with IoT:

- Enhanced capabilities for devices that require real-time data transmission and connectivity.

- Ability to create modular designs that can be easily updated or modified.

Advanced Manufacturing Techniques:

- Integration with 3D printing technologies, allowing for the seamless bonding of printed parts.

- Use in additive manufacturing to create complex geometries that traditional methods cannot achieve.

Customization and Tailored Solutions:

- Ability to develop specific formulations to meet unique industry needs, such as aerospace or medical applications.

- Enhanced customization options allow for the creation of specialized adhesives for unique materials or bonding requirements.

Impact on Various Industries

Automotive:

- Greater emphasis on lightweight materials and efficient assembly processes.

- Magnetic adhesive solutions can streamline the production of electric vehicles and reduce weight.

Electronics:

- Rise in miniaturization of devices where space-saving solutions are crucial.

- Magnetic bonding can facilitate the development of compact, multifunctional devices.

Medical:

- Increased demand for medical devices that require strong bonds and the ability to integrate magnetic features.

- Opportunities for innovative solutions in patient monitoring and diagnostic tools.

Challenges Ahead

While the future of Magnetic Iron Bonding Adhesive is promising, some challenges need to be addressed:

Regulatory Compliance:

- Adapting to stringent regulations in aerospace and medical industries requires rigorous testing and validation of materials.

Market Education:

- They are educating manufacturers and end-users about the benefits and applications of Magnetic Iron Bonding Adhesive to encourage adoption.

Competition:

- We are staying ahead in a competitive market where traditional adhesives may still dominate due to familiarity and cost.

Conclusion

Magnetic Iron Bonding Adhesive represents a significant advancement in adhesive technology, combining robust bonding capabilities with unique magnetic properties. Its diverse applications across various industries highlight its versatility and effectiveness. As manufacturing and technology evolve, the demand for innovative solutions like Magnetic Iron Bonding Adhesive will only grow. By understanding its properties, applications, and considerations, manufacturers and builders can harness the full potential of this remarkable adhesive, paving the way for future innovations in design and functionality.Whether in automotive, electronics, or any industry that relies on strong and flexible bonding solutions, Magnetic Iron Bonding Adhesive could be the game-changer you need. Embrace the future of adhesion technology and explore how this adhesive can enhance your projects today.

For more about choosing the power of magnetic iron bonding adhesive: a comprehensive guide, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.