Low Viscosity UV Silicone Glue: The Invisible Bond Transforming Precision Manufacturing

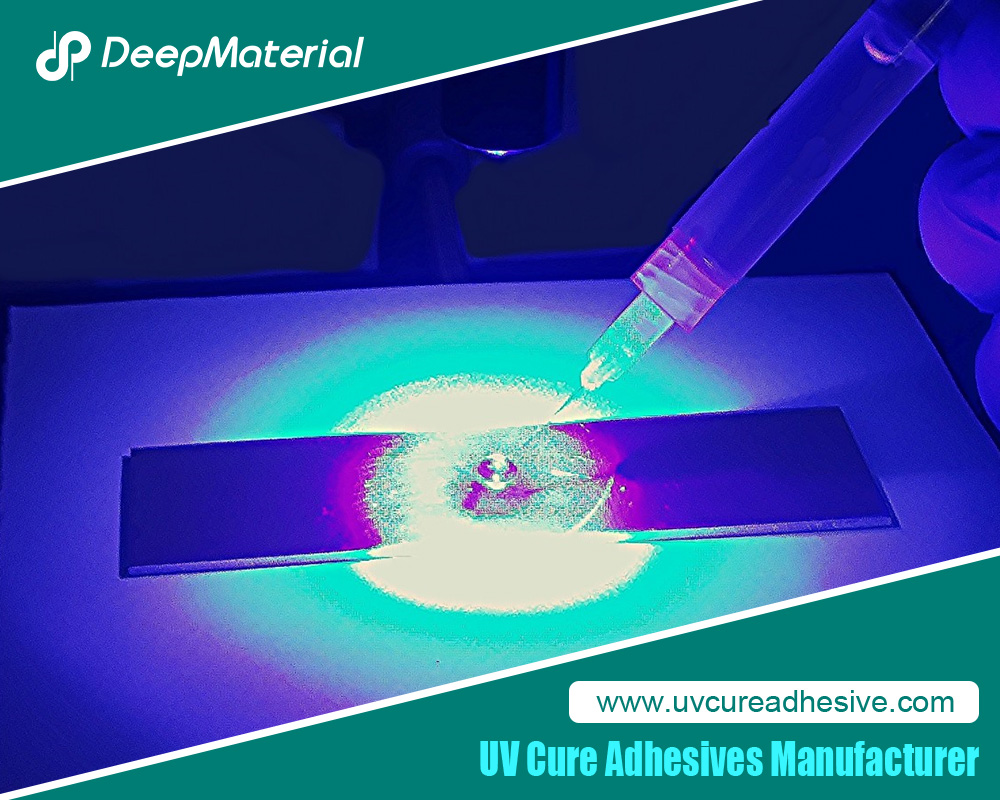

In the ever-evolving landscape of industrial adhesives, a remarkable material has emerged that combines unique properties with unprecedented application precision: low viscosity UV silicone glue. This advanced adhesive represents a convergence of material science and photopolymerization technology, offering solutions to bonding challenges that were previously insurmountable. Unlike conventional adhesives that rely on evaporation, chemical reaction, or heat curing, UV silicone glue harnesses the power of ultraviolet light to create strong, flexible bonds in seconds. Its low viscosity—typically ranging from 50 to 500 centipoise—allows it to flow effortlessly into microscopic spaces and complex geometries, making it indispensable in industries where precision is paramount. From delicate medical devices to sophisticated electronics, this transparent, versatile adhesive is quietly revolutionizing how we assemble the technologies that define modern life.

Understanding the Material: What Makes UV Silicone Glique Unique?

Chemical Foundation

Low viscosity UV silicone glue is based on modified silicone polymers that incorporate photoreactive functional groups, typically acrylate or methacrylate moieties. These specialized silicones retain the inherent beneficial properties of traditional silicone—excellent thermal stability, flexibility, and resistance to environmental factors—while gaining the ability to cure rapidly when exposed to UV light of specific wavelengths, usually between 320-400 nm. The formulation includes photoinitiators that absorb UV energy and generate reactive species, triggering a polymerization cascade that transforms the liquid resin into a solid elastomer within seconds. This dual nature—combining silicone’s material advantages with UV curability—creates a unique adhesive category with capabilities unmatched by other bonding technologies.

Viscosity Characteristics

The “low viscosity” designation typically refers to adhesives with viscosity below 1000 centipoise (cP), with many specialized formulations measuring between 50-500 cP. For comparison, water has a viscosity of approximately 1 cP at room temperature, while honey ranges from 2,000-10,000 cP. This fluidity enables the adhesive to wick into gaps as narrow as 10 microns through capillary action, coat irregular surfaces uniformly, and self-level before curing. Manufacturers achieve these low viscosities through careful molecular design that minimizes chain entanglement and strategic use of reactive diluents that reduce thickness without compromising final properties.

Curing Mechanism

The curing process occurs in distinct stages. Initially, the liquid adhesive is applied to the substrate. Upon UV exposure, photoinitiators absorb photons and generate free radicals or cations (depending on the chemistry). These reactive centers attack the double bonds in the silicone-acrylate hybrid molecules, initiating a chain-growth polymerization. The process propagates rapidly as more monomers join the growing polymer chains, eventually forming a three-dimensional network. Curing depth depends on the adhesive’s transparency to UV light and the intensity of the radiation source. Unlike thermal-cure silicones that require hours at elevated temperatures, UV silicones achieve handling strength in seconds and full cure typically within 24 hours as any shadowed areas complete curing through oxygen inhibition or residual initiator activity.

Key Properties and Advantages

Exceptional Flexibility and Elasticity

Once cured, low viscosity UV silicone glue maintains remarkable elasticity, typically exhibiting elongation at break values between 100-500%. This allows bonded assemblies to withstand substantial thermal expansion mismatches, mechanical shock, vibration, and flexing without adhesive failure. The silicone backbone provides a low modulus (often 1-10 MPa) that distributes stress efficiently across bonded areas, making it ideal for bonding dissimilar materials with different coefficients of thermal expansion.

Optical Clarity and Transparency

Most formulations achieve transparency exceeding 90% across the visible spectrum, with some grades offering over 98% light transmission. This optical clarity, combined with minimal yellowing upon aging or UV exposure, makes these adhesives perfect for optical applications, display assembly, and situations where bond lines must remain invisible. The refractive index can be tailored between 1.41-1.53 to match various glass and plastic substrates, minimizing light scattering at interfaces.

Thermal and Environmental Stability

UV silicone adhesives perform consistently across extreme temperature ranges, typically from -50°C to +200°C, with specialized formulations extending to 300°C. They maintain flexibility and adhesion even at cryogenic temperatures while resisting thermal degradation at high temperatures. Their inherent hydrophobicity and chemical structure provide excellent resistance to moisture, humidity, oxidation, and many chemicals, including acids, bases, and solvents. Unlike polyurethane or epoxy adhesives, silicones do not hydrolyze or degrade significantly in humid environments, ensuring long-term reliability in challenging conditions.

Biocompatibility and Safety

Many low viscosity UV silicone glues are formulated to meet ISO 10993 and USP Class VI biocompatibility standards, making them suitable for medical device assembly. They exhibit low cytotoxicity, minimal extractables, and excellent stability in physiological environments. Their rapid curing at room temperature eliminates thermal stress on sensitive components, while their low viscosity allows precise application without excessive pressure that might damage delicate parts.

Electrical Properties

With volume resistivity exceeding 10^14 ohm-cm and dielectric strength over 20 kV/mm, cured UV silicone adhesives provide excellent electrical insulation. Their stable dielectric constant (typically 2.7-3.2) across wide frequency and temperature ranges makes them valuable in electronic applications where consistent performance is critical. These properties remain stable even in high humidity environments where other insulators might degrade.

Applications Across Industries

Medical Device Manufacturing

The medical industry has embraced low viscosity UV silicone glue for assembling increasingly miniaturized and complex devices. Its biocompatibility allows direct use in implants, surgical tools, diagnostic equipment, and wearable medical devices. Specific applications include:

- Bonding needles to syringe hubs without occluding lumens

- Assembling microfluidic chips for lab-on-a-chip diagnostics

- Sealing and insulating pacemaker components and neurostimulators

- Attaching lenses and sensors in endoscopic cameras

- Encapsulating delicate electronic components in monitoring devices

The adhesive’s ability to cure on demand with minimal heat generation protects sensitive biological samples and electronic components during assembly. Its flexibility accommodates sterilization processes (autoclave, gamma, or ETO) without embrittlement or bond failure.

Electronics and Microelectronics

As electronic devices shrink and component density increases, traditional soldering and adhesives reach their practical limits. Low viscosity UV silicone glue addresses these challenges through:

- Underfilling and glob-topping for chip-on-board (COB) and flip-chip assemblies

- Potting and encapsulating sensors, MEMS devices, and fragile components

- Bonding optical elements in smartphone cameras and displays

- Sealing connectors and providing strain relief for cables

- Insulating high-voltage components in compact power supplies

The material’s combination of electrical insulation, thermal stability, and mechanical shock absorption protects sensitive electronics in automotive, aerospace, and consumer applications. Its low ionic content prevents corrosion and electrochemical migration that can cause device failure.

Optics and Photonics

In optical systems where precise alignment and minimal stress are critical, low viscosity UV silicone glue offers unique advantages:

- Bonding lenses, prisms, and optical fibers with sub-micron precision

- Assembling augmented and virtual reality displays

- Fabricating fiber optic connectors and splices

- Mounting laser diodes and other photonic components

- Sealing optical windows in harsh environments

The adhesive’s transparency, controllable refractive index, and minimal shrinkage during cure maintain optical alignment and prevent image distortion. Its flexibility accommodates differential thermal expansion between optical materials like glass, crystals, and metals.

Automotive and Aerospace

Modern vehicles and aircraft incorporate increasing amounts of electronics, sensors, and advanced materials that require reliable bonding solutions:

- Sealing and potting sensors for engine management, ADAS, and infotainment systems

- Bonding lightweight composite materials in structural applications

- Assembling LED lighting modules with superior thermal management

- Encapsulating control modules exposed to vibration and temperature cycling

- Bonding decorative trim and emblems without visible attachment points

The adhesive’s performance across extreme temperatures (-40°C to 150°C in automotive, -55°C to 200°C in aerospace) and resistance to fuels, lubricants, and cleaning agents ensure long-term reliability in demanding environments.

Consumer Electronics and Wearables

The relentless drive toward thinner, lighter, and more durable consumer products has made low viscosity UV silicone glue essential for:

- Waterproofing smartwatches, fitness trackers, and hearing aids

- Bonding displays to frames in smartphones and tablets

- Assembling true wireless earbuds and other miniature audio devices

- Sealing connections in IoT devices and smart home sensors

- Attaching flexible components in foldable displays

The adhesive’s combination of durability, flexibility, and rapid curing supports high-volume manufacturing while meeting consumer expectations for product longevity and reliability.

Selection Criteria: Choosing the Right Formulation

Viscosity and Flow Characteristics

Selecting the appropriate viscosity depends on application requirements. Lower viscosities (50-200 cP) excel at capillary wicking into tight gaps, coating complex geometries, and filling microscopic voids. Medium viscosities (200-500 cP) offer better control on vertical surfaces and reduced dripping. Application method also influences selection—dispensing needles, jetting valves, and screen printing each have optimal viscosity ranges. Understanding the substrate wetting characteristics and required flow distance before gelation is crucial for process design.

Cure Speed and Depth

Cure parameters vary significantly between formulations. Standard products may cure in 5-30 seconds under 100 mW/cm² UV-A exposure, while fast-cure versions achieve handling strength in 1-5 seconds. Cure depth—the maximum thickness that cures completely—ranges from 1 mm for opaque or filled formulations to 10+ mm for highly transparent grades. Applications involving shadowed areas may require dual-cure formulations that combine UV initiation with secondary moisture or thermal curing mechanisms.

Mechanical Properties

Final material properties should match application stresses. Key considerations include:

- Shore hardness (typically 20A-50A for flexible bonds, 60A-80D for rigid assemblies)

- Tensile strength (0.5-5 MPa for most flexible formulations)

- Elongation at break (100-500% for stress-relieving applications)

- Tear strength (10-30 kN/m for durable seals)

- Bond strength to specific substrates (glass, metals, plastics, ceramics)

Specialty formulations offer enhanced properties like thermal conductivity (up to 3 W/mK for heat dissipation), electrically conductivity (for EMI shielding or grounding), or fluorescence (for inspection under UV light).

Chemical and Environmental Resistance

Different applications demand specific resistance profiles. Medical devices require biocompatibility and sterilization resistance. Automotive applications need fuel and oil resistance. Outdoor electronics demand UV stability and moisture barrier properties. Aerospace applications require outgassing certification for vacuum environments. Matching the adhesive’s resistance profile to the service environment prevents premature failure.

Regulatory Compliance

Depending on the industry, adhesives may need to comply with various regulations:

- FDA 21 CFR 175.105/300 for indirect food contact

- USP Class VI and ISO 10993 for medical devices

- UL 94 V-0 for flame retardancy in electronics

- RoHS, REACH, and Proposition 65 for hazardous substance restrictions

- NASA outgassing standards for aerospace applications

Application Techniques and Best Practices

Surface Preparation

Despite silicone’s generally good adhesion, surface preparation significantly enhances bond strength and longevity:

- Clean surfaces thoroughly with isopropyl alcohol or specialized cleaners to remove oils, mold releases, and processing residues

- For challenging substrates like polyolefins or some metals, apply primers or use plasma/ corona treatment to increase surface energy

- Ensure surfaces are completely dry before application, as moisture can interfere with cure

- For optimal wetting, surfaces should have energy exceeding the adhesive’s surface tension (typically 20-30 dynes/cm)

Dispensing Methods

Precision dispensing is critical for low viscosity materials:

- Time-pressure dispensers: Simple but inconsistent for low viscosity materials

- Auger valve dispensers: Better control through positive displacement

- Jet dispensing: Non-contact deposition of dots or lines at high speed

- Screen printing: For coating larger areas with precise thickness control

- Needle dispensing: For accessing confined spaces with minimal waste

Dispensing parameters (pressure, time, needle size) must be optimized to prevent dripping, stringing, or inconsistent deposits. Heated dispensers (30-40°C) can temporarily reduce viscosity for improved flow in complex paths.

Curing Equipment and Process Control

Effective curing requires appropriate UV sources and exposure control:

- LED UV lamps: Offer precise wavelength control, minimal heat generation, instant on/off capability, and long life

- Mercury arc lamps: Broad spectrum output but generate significant heat and degrade over time

- Microwave-powered lamps: High intensity but require careful thermal management

Critical curing parameters include:

- Irradiance (mW/cm²): Determines cure speed

- Dose (J/cm²): Total energy delivered, affecting depth of cure

- Wavelength spectrum: Must match photoinitiator absorption

- Temperature: Affects viscosity during application and cure rate

For complex 3D assemblies, multi-directional exposure or rotating fixtures ensure complete curing in shadowed areas. Dual-cure formulations provide insurance for areas with limited UV access.

Quality Control and Inspection

Ensuring consistent bond quality requires:

- Monitoring adhesive viscosity, pot life, and storage conditions

- Calibrating dispensing equipment regularly

- Verifying UV lamp output with radiometers

- Conducting destructive testing of sample bonds

- Using UV fluorescence to inspect coverage in transparent assemblies

- Performing environmental testing (thermal cycling, humidity, vibration) on finished assemblies

Challenges and Limitations

Oxygen Inhibition

Surface cure can be inhibited by atmospheric oxygen, leaving a tacky layer. Solutions include:

- Using nitrogen-purged curing chambers

- Selecting formulations with wax additives that migrate to form a barrier

- Applying secondary curing mechanisms (moisture, heat)

- Post-curing with longer wavelength UV that penetrates the inhibited layer

Substrate Limitations

While adhesion to glass, metals, and many plastics is excellent, some materials present challenges:

- Polyolefins (PP, PE) require surface treatment

- Silicone substrates need specially formulated adhesives

- Some thermoplastic elastomers may have migrating additives that interfere with bonding

- Porous materials can wick adhesive away from bond lines

Thermal and Chemical Constraints

Although superior to many alternatives, UV silicones have limits:

- Continuous service temperature typically maxes at 200°C (higher for specialty grades)

- Strong acids, bases, and solvents can eventually degrade bonds

- UV transparency limits filler loading, affecting thermal or electrical properties

- Long-term UV exposure can cause gradual yellowing in some formulations

Process Considerations

Manufacturing challenges include:

- Managing very low viscosity materials without dripping or contamination

- Ensuring complete cure in complex geometries with shadowed areas

- Achieving consistent bond line thickness for optical or mechanical precision

- Controlling cleanliness in medical and electronic applications

- Managing shelf life and pot life for materials sensitive to ambient UV

Future Developments and Trends

Advanced Material Science

Research continues to expand the capabilities of low viscosity UV silicone glues:

- Self-healing formulations: Incorporating reversible bonds that repair minor damage

- Stimuli-responsive adhesives: Changing properties in response to temperature, pH, or other triggers

- Bio-based silicones: Reducing environmental impact through renewable feedstocks

- Enhanced functionality: Combining adhesion with sensing, energy harvesting, or data transmission capabilities

- Nanocomposite formulations: Incorporating nanoparticles for improved thermal, electrical, or mechanical properties

Manufacturing Innovations

Application technologies are evolving to leverage the unique properties of these adhesives:

- 3D printing: Using UV silicone as a printable material for flexible structures

- Roll-to-roll processing: Enabling high-volume production of flexible electronics

- Automated inspection: Machine vision systems for real-time quality control

- Adaptive dispensing: Systems that adjust parameters based on environmental conditions or part variations

- Integrated curing: Combining multiple wavelength sources for optimized through-cure

Sustainability Initiatives

The adhesive industry is addressing environmental concerns through:

- Reduced VOC formulations: Minimizing volatile organic compounds

- Recyclable bonding: Designing disassembly capabilities into bonded products

- Energy efficiency: Faster curing formulations that reduce manufacturing energy consumption

- Circular economy: Developing debonding technologies for repair and recycling

- Green chemistry: Safer raw materials and manufacturing processes

Conclusion

Low viscosity UV silicone glue represents a remarkable convergence of material properties that addresses the increasingly complex bonding challenges of modern technology. Its unique combination of fluidity, rapid curing, flexibility, transparency, and environmental stability has made it indispensable across industries from medical devices to aerospace. As manufacturing demands continue toward miniaturization, increased functionality, and enhanced reliability, the role of this advanced adhesive will only expand.

The ongoing evolution of UV silicone technology—driven by advances in polymer chemistry, application equipment, and process control—promises to unlock new capabilities and applications. From enabling the next generation of flexible electronics to supporting life-saving medical innovations, low viscosity UV silicone glue serves as an invisible yet essential enabler of technological progress.

For engineers, designers, and manufacturers, understanding this material’s capabilities, limitations, and proper application techniques is increasingly important. As with any advanced material, success depends not just on selecting the right formulation, but on integrating it into a holistic manufacturing process that considers surface preparation, dispensing, curing, and quality assurance. When properly implemented, low viscosity UV silicone glue provides bonds that are not just strong, but smart—adapting to thermal stresses, protecting sensitive components, and maintaining integrity in challenging environments.

In an era where the interfaces between materials often determine product success or failure, this remarkable adhesive continues to push the boundaries of what’s possible in precision manufacturing, offering solutions that are as elegant in their simplicity as they are sophisticated in their performance.

For more about low viscosity uv silicone glue: the invisible bond transforming precision manufacturing, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.