UV Adhesive for Glass: A Comprehensive Guide

UV or ultraviolet adhesive is a versatile bonding solution widely used in various industries. Due to its unique properties and advantages, it is trendy in glass applications. This article delves into the world of UV adhesive for glass, exploring its composition, benefits, applications, and best practices for usage.

What is UV Adhesive?

UV adhesive is a type of adhesive that cures or hardens when exposed to ultraviolet light. Unlike traditional adhesives that require heat, pressure, or solvents to cure, UV adhesives rely solely on UV light to initiate the polymerization process. This makes them highly efficient and suitable for delicate applications where heat or pressure might cause damage.

Composition of UV Adhesive

UV adhesives are typically composed of:

- Monomers and Oligomersare the primary building blocks polymerizing under UV light to form a solid bond.

- Photoinitiators:These chemicals absorb UV light and generate reactive species that start polymerization.

- Additives:These can include stabilizers, adhesion promoters, and other modifiers to enhance the adhesive’s properties.

Benefits of Using UV Adhesive for Glass

UV adhesives offer several advantages when used for bonding glass:

- Rapid Curing:UV adhesives cure almost instantaneously when exposed to UV light, significantly reducing assembly time.

- Strong Bond:They form durable bonds that withstand various environmental conditions, including moisture and temperature fluctuations.

- Clear and Transparent:UV adhesives cure an evident, invisible bond crucial for aesthetic applications involving glass.

- Versatility:They can bond not only glass but also various other materials, such as metals, plastics, and ceramics, making them ideal for mixed-material assemblies.

- Precision:Curing on demand allows for precise alignment and positioning of glass components before bonding.

- Low Shrinkage:Minimal shrinkage during curing ensures that the bond line remains consistent and stress-free.

Applications of UV Adhesive in Glass Bonding

UV adhesives are used in a wide range of applications involving glass. Some of the most common include:

Optical and Photonics Industries

Precision and clarity are paramount in the optical and photonics industries. UV adhesives bond lenses, prisms, and other optical components without compromising their optical properties. Their ability to cure quickly and form strong, transparent bonds makes them ideal for these applications.

Electronics

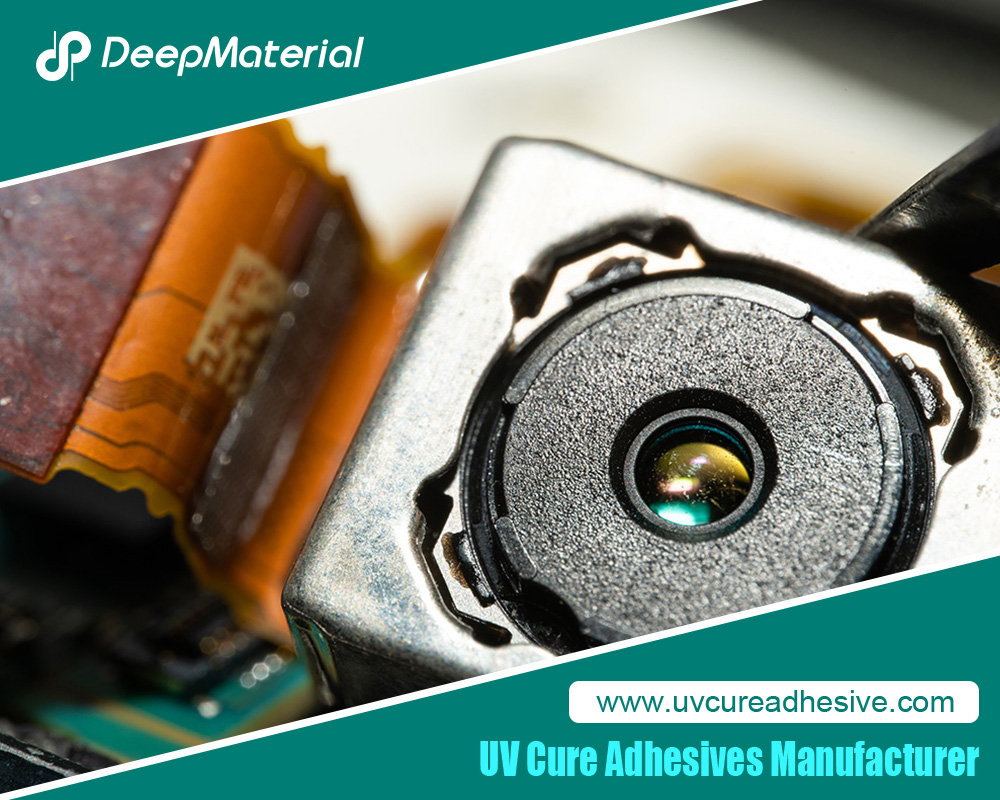

In the electronics industry, UV adhesives assemble and encapsulate delicate components. They provide a reliable bond without high temperatures, which can damage sensitive electronics. Applications include bonding display screens, touch panels, and camera modules.

Automotive Industry

UV adhesives are used in the automotive industry to bond windows, mirrors, and decorative glass panels. Their resistance to environmental factors like UV radiation, moisture, and temperature changes ensures long-lasting performance in automotive applications.

Medical Devices

In the medical field, UV adhesives assemble and seal glass components in medical devices, such as syringes, catheters, and diagnostic equipment. Their rapid curing and biocompatibility make them suitable for medical applications where sterility and precision are critical.

Decorative and Architectural Glass

UV adhesives provide a clear and durable bond for decorative and architectural glass applications. They are used to create glass furniture, glass partitions, and decorative glass elements in buildings, offering aesthetic appeal and structural integrity.

Choosing the Right UV Adhesive for Glass

Selecting the appropriate UV adhesive for a specific glass bonding application involves considering several factors:

Bonding Strength

Different applications require different levels of bonding strength. Choosing a UV adhesive that provides the necessary stability for the intended use is essential. For example, structural applications may require higher-strength adhesives than decorative applications.

Viscosity

The adhesive’s viscosity determines how it flows and spreads between the glass surfaces. Low-viscosity adhesives are suitable for tight joints and capillary action, while higher-viscosity adhesives are better for filling gaps and providing structural support.

Curing Time

The curing time depends on the intensity and wavelength of the UV light source and the adhesive’s formulation. Some applications may require rapid curing, while others may benefit from a slower process to ensure proper alignment and positioning.

Optical Properties

For applications where optical clarity is essential, such as bonding lenses or display screens, it’s crucial to choose a UV adhesive with excellent optical properties, including low haze and high transparency.

Environmental Resistance

Consider the environmental conditions the bonded assembly will be exposed to, such as temperature fluctuations, moisture, and UV radiation. Choose a UV adhesive that resists these factors to ensure long-term durability.

Best Practices for Using UV Adhesive on Glass

To achieve optimal results when using UV adhesive for glass bonding, follow these best practices:

Surface Preparation

Proper surface preparation is critical for achieving a solid bond. Clean the glass surfaces thoroughly to remove contaminants like dust, oils, or fingerprints. Use solvents like isopropyl alcohol to ensure a clean surface.

Application Technique

Apply the adhesive evenly to ensure complete coverage of the bonding area. Avoid air bubbles, which can weaken the bond and compromise the optical clarity. Use appropriate dispensing equipment such as syringes or automated dispensers for precise application.

UV Light Exposure

Ensure that the adhesive is exposed to the correct intensity and wavelength of UV light for the recommended duration. Use a UV light source with consistent output to achieve uniform curing. Shield the assembly from ambient light until the adhesive is cured to prevent premature curing.

Bond Line Thickness

Maintain a consistent bond line thickness to ensure uniform curing and strength. Use spacers or shims to achieve the desired bond line thickness if necessary.

Post-Curing Handling

After curing, handle the bonded assembly carefully to avoid applying excessive stress to the bond. Allow sufficient time for the adhesive to fully cure and reach its maximum strength before subjecting the assembly to any load or stress.

Innovations and Future Trends in UV Adhesives for Glass

UV adhesives continuously evolve, with ongoing research and development leading to innovations and improvements. Some emerging trends in UV adhesives for glass include:

Eco-Friendly Formulations

There is a growing emphasis on developing eco-friendly UV adhesives that reduce environmental impact. These formulations aim to minimize the use of hazardous chemicals and promote sustainability without compromising performance.

Advanced Photoinitiators

Research is focused on developing advanced photoinitiators that enhance UV adhesives’ curing efficiency and depth. These new photoinitiators can improve the adhesive’s performance in challenging applications, such as thick bond lines or opaque substrates.

Smart Adhesives

Innovative adhesives that respond to external stimuli, such as temperature or humidity, are gaining interest. These adhesives can offer adaptive bonding properties, making them suitable for dynamic environments where conditions change over time.

Improved Optical Properties

Innovations in adhesive chemistry aim to enhance the optical properties of UV adhesives, such as reducing yellowing over time and improving light transmission. These improvements are significant for applications in the optical and electronics industries.

Hybrid Adhesives

Hybrid adhesives that combine UV curing with other curing mechanisms, such as heat or moisture, are being developed to offer more versatile bonding solutions. These adhesives can provide enhanced performance and reliability in complex applications.

Conclusion

UV adhesive for glass is a powerful and versatile bonding solution that offers numerous benefits, including rapid curing, strong bonds, and optical clarity. Its applications span various industries, from electronics and automotive to medical devices and decorative glass. Users can achieve optimal results in their glass bonding projects by understanding the critical factors in selecting and using UV adhesives and staying informed about emerging trends. UV adhesives will likely see further innovations as technology advances, making them an even more indispensable tool in glass bonding.

For more about choosing the UV adhesive for glass: a comprehensive guide, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.