The Future of Sound: Exploring Smart Speaker Assembly Adhesive

In the age of intelligent technology, our homes have transformed into connectivity, convenience, and entertainment hubs. At the heart of this evolution are smart speakers, devices that amplify our favorite tunes and act as the control center for our smart homes. However, behind the sleek exterior of these devices lies an often-overlooked component: the smart speaker assembly adhesive. This specialized adhesive ensures durability, sound quality, and functionality. This article will explore the significance of smart speaker assembly adhesive, its various applications and types, and the innovations shaping its future.

The Importance of Smart Speaker Assembly Adhesive

Structural Integrity

- Ensuring Durability:Smart speakers are subjected to regular handling and environmental factors. The suitable adhesive maintains the device’s structural integrity, preventing disassembly over time.

- Resilience Against Environmental Factors:High-quality adhesives are designed to withstand temperature fluctuations, humidity, and exposure to dust and debris.

- Acoustic Performance

- Sound Quality Enhancement:The choice of adhesive can influence the sound quality. Some adhesives are engineered to minimize vibration and resonance, ensuring clearer audio.

- Sealing for Sound Isolation:A proper adhesive seals gaps that can cause sound leakage, enhancing the speaker’s overall acoustic performance.

Ease of Assembly

- Streamlining Manufacturing:Using an effective assembly adhesive simplifies the manufacturing process. It allows for quicker assembly times and reduces the need for mechanical fasteners.

- Design Flexibility:Adhesives give design engineers greater flexibility in shapes and materials, enabling more innovative product designs.

Types of Smart Speaker Assembly Adhesives

Epoxy Adhesives

- High Strength:Epoxy adhesives are known for their strong bonding capabilities, making them ideal for structural components.

- Chemical Resistance:These adhesives can resist various chemicals, which is beneficial for smart speakers that may be used in different environments.

Polyurethane Adhesives

- Elasticity:Polyurethane adhesives offer excellent elasticity, making them suitable for flexible applications.

- Water Resistance:These adhesives are often moisture-resistant, providing additional protection for electronic components.

Silicone Adhesives

- Temperature Resistance:Silicone adhesives can withstand extreme temperatures, making them suitable for smart speakers exposed to heat sources.

- Vibration Damping:Their unique properties help absorb vibrations and enhance sound quality.

Acrylic Adhesives

- Fast Curing:Acrylic adhesives cure quickly, which speeds up the assembly process.

- Precise Bonding:These adhesives provide a clear finish, making them ideal for applications where aesthetics matter.

Innovations in Smart Speaker Assembly Adhesive Technology

Nanotechnology

- Enhanced Properties:Nanotechnology in adhesives can significantly improve adhesion strength, flexibility, and resistance to environmental factors.

- Innovative Adhesives:Future innovations may lead to adhesive development that can self-heal or change properties based on environmental conditions.

Environmentally Friendly Options

- Bio-based Adhesives:With the increasing focus on sustainability, manufacturers are exploring bio-based adhesives that reduce environmental impact.

- Recyclability: New adhesive formulations are designed to be more easily recyclable, contributing to a circular economy.

Integration with Smart Technologies

- Sensor Integration:Future adhesives may incorporate sensors that monitor structural integrity, providing real-time data on the speaker’s condition.

- Adaptive Properties:Smart adhesives could adapt their properties based on temperature or humidity, ensuring optimal performance in varying conditions.

The Manufacturing Process of Smart Speaker Assembly Adhesive

Preparation

- Surface Cleaning:Proper surface preparation is crucial for optimal adhesion. Manufacturers must ensure that surfaces are clean and free from contaminants.

- Adhesive Selection:The appropriate adhesive type is selected based on the bonded materials and the specific application requirements.

Application

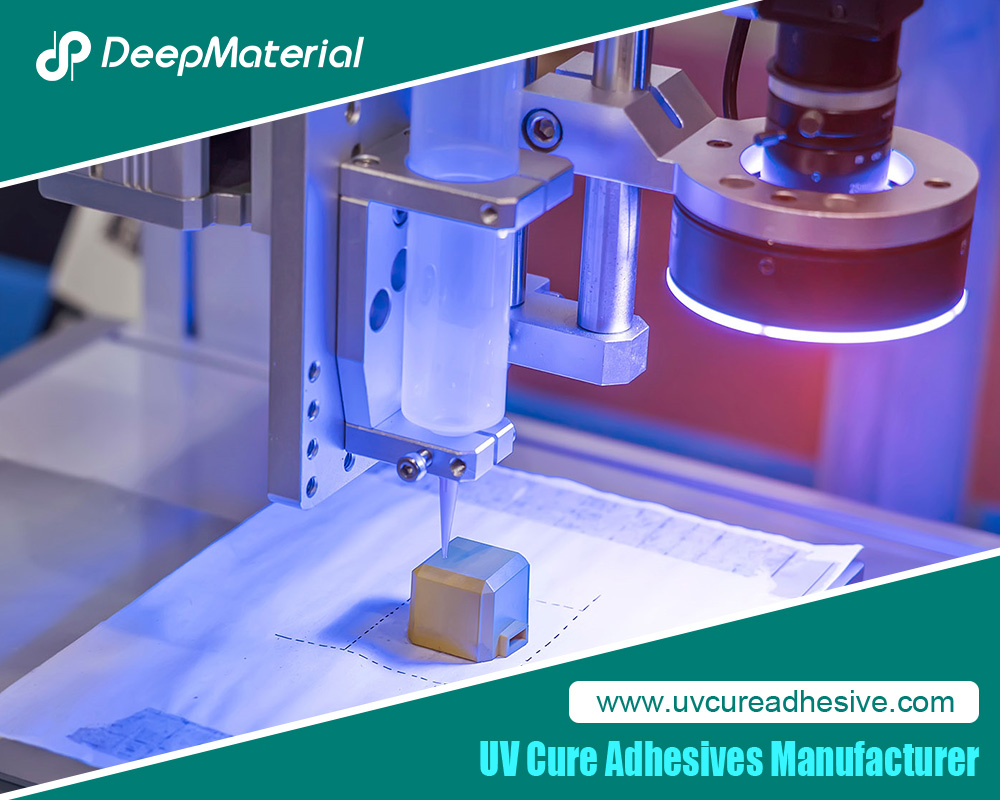

- Automated Dispensing:Many manufacturers use automated systems to dispense adhesives precisely, ensuring consistent application.

- Curing Methods:Depending on the adhesive type, various curing methods (e.g., heat, UV light) are employed to achieve a strong bond.

Quality Control

- Testing:Rigorous testing assesses the adhesive’s bond strength, durability, and performance in real-world conditions.

- Inspection:Visual inspections and advanced imaging techniques ensure no defects in the adhesive application.

Challenges and Considerations

Material Compatibility

- Adhesive-Substrate Interaction:Compatibility between the adhesive and the materials used in smart speakers is essential to prevent failures.

- Aging Effects:Some adhesives may degrade over time, impacting the speaker’s longevity and performance.

Regulatory Compliance

- Environmental Regulations:Manufacturers must comply with regulations governing the use of adhesives, especially about volatile organic compounds (VOCs).

- Safety Standards:Compliance with safety standards is critical, particularly for products used in consumer electronics.

Market Competition

- Cost vs. Performance:Manufacturers face the challenge of balancing cost-effectiveness with high-performance requirements in adhesive solutions.

- Innovation Pace:The rapid pace of technological innovation demands that adhesive manufacturers continually adapt and evolve their products.

The Future of Smart Speaker Assembly Adhesive: Trends and Predictions

As the demand for smart speakers continues to rise, so does the necessity for innovative assembly adhesives that meet the evolving needs of manufacturers and consumers. Here are some key trends and predictions shaping the future of smart speaker assembly adhesive technology:

Integration of Smart Technologies:

- Sensor-Embedded Adhesives:Future adhesives may incorporate smart sensors that monitor environmental conditions, providing real-time data on temperature, humidity, and structural integrity.

- Adaptive Properties:Innovations could lead to adhesives that automatically adjust their properties in response to environmental changes, ensuring optimal bonding and performance.

Emphasis on Sustainability:

- Bio-Based Adhesives:The shift towards sustainability will likely accelerate the development of bio-based adhesives from renewable resources, reducing reliance on petrochemicals.

- Lower Environmental Impact:Manufacturers must prioritize adhesives with lower VOC emissions and eco-friendly profiles, appealing to environmentally conscious consumers.

Advanced Manufacturing Techniques:

- 3D Printing of Adhesives:The rise of 3D printing technology may enable on-demand production of customized adhesives, allowing manufacturers to tailor adhesive properties to specific applications.

- Automated Application Processes:Enhanced automation in adhesive applications will streamline manufacturing, reduce waste, and ensure consistent quality across production lines.

Customization and Versatility:

- Tailored Adhesive Solutions:As smart speaker designs become more complex, manufacturers will seek adhesives that can bond a wider variety of materials and withstand different environmental stresses.

- Multi-Functional Adhesives:The future may see the emergence of adhesives that serve multiple purposes—acting not only as bonding agents but also as insulators or sound dampeners.

Enhanced Testing and Quality Control:

- Real-Time Monitoring:New technologies may allow for real-time monitoring of adhesive performance during manufacturing, enabling immediate adjustments and quality assurance.

- Advanced Testing Methods:Developing more sophisticated testing methods will ensure that adhesives can withstand extreme conditions, providing confidence in product longevity and reliability.

Consumer-Centric Design:

- Focus on User Experience: As smart speakers evolve, adhesives must support designs that enhance user experience, including sleek aesthetics and improved acoustic performance.

- Customizable Features:Manufacturers may explore adhesives that allow for customization in design, giving consumers options to personalize their devices.

- Collaboration Across Industries:

- Cross-Disciplinary Innovation:Collaborations between adhesive manufacturers, electronics designers, and environmental scientists may yield groundbreaking adhesive technologies that align with modern consumer needs.

- Knowledge Sharing:Industry-wide initiatives and partnerships can facilitate sharing best practices, leading to improved adhesive formulations and applications.

Conclusion

Smart speaker assembly adhesive is more than just a bonding agent; it is a vital component that influences modern smart speakers’ durability, performance, and innovation. As technology advances, the demand for specialized adhesives that meet the needs of evolving consumer electronics will only grow. From enhancing sound quality to enabling innovative designs, smart speaker assembly adhesive plays a crucial role in shaping the future of sound technology. By embracing advancements in adhesive technology and considering environmental impacts, manufacturers can ensure that smart speakers remain at the forefront of our connected lives. As we look ahead, it is clear that the evolution of smart speaker assembly adhesive will continue to drive the audio experience, making our interactions with technology more seamless and enjoyable.

For more about choosing the future of sound: exploring smart speaker assembly adhesive, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.