Understanding Optical Bonding Adhesive: A Comprehensive Overview

Modern technology is ever-evolving, and the pursuit of clarity and durability in displays is no exception. One significant innovation in this field is optical bonding adhesive, a material designed to enhance the performance and longevity of displays across various applications. By seamlessly adhering layers within electronic devices, optical bonding adhesives improve optical quality and resistance to environmental challenges. This article delves into the multifaceted aspects of optical bonding adhesive, exploring its benefits, applications, types, and future trends.

What is Optical Bonding Adhesive?

Optical bonding adhesive is a specialized adhesive used to bond layers of display screens to enhance visibility and protect against environmental factors. This adhesive ensures that the various layers, including the cover glass and LCD or OLED screens, adhere without air gaps. By eliminating these gaps, optical bonding adhesives significantly reduce reflections and improve light transmission through the display, resulting in more explicit images and better overall performance.

Critical Characteristics of Optical Bonding Adhesives

- Transparency: Optical bonding adhesives are designed to be highly transparent, allowing maximum light transmission without distorting colors.

- Durability: These adhesives resist environmental conditions, including temperature fluctuations, humidity, and UV exposure.

- Adhesion Strength: They provide strong adhesion between layers, ensuring that displays maintain structural integrity over time.

- Flexibility:Optical bonding adhesives can accommodate materials’ thermal expansion and contraction, reducing the risk of delamination.

Benefits of Using Optical Bonding Adhesives

The use of optical bonding adhesive in display technologies offers numerous benefits that can enhance electronic devices’ functionality and longevity.

Improved Optical Performance

- Enhanced Clarity: By minimizing air gaps, optical bonding adhesives eliminate light scattering, resulting in sharper images and vibrant colors.

- Reduced Glare: The adhesive creates a single optical layer, which reduces reflections and glare, improving visibility in bright environments.

Increased Durability and Protection

- Impact Resistance:Optical bonding enhances the durability of displays, making them more resistant to scratches and impacts.

- Environmental Protection: Displays bonded with optical adhesives are better protected against moisture and dust ingress, which can lead to device failures.

Weight Reduction

- Thinner Displays:Optical bonding adhesives allow for thinner display constructions, reducing overall device weight without compromising quality.

Cost-Effectiveness

- Long-Term Savings: While the initial investment in optical bonding technology may be higher, the long-term benefits of reduced warranty claims and device failures often lead to significant cost savings.

Applications of Optical Bonding Adhesives

Optical bonding adhesives are employed across various industries, underscoring their versatility and effectiveness.

Consumer Electronics

- Smartphones and Tablets:Optical bonding is widely used in smartphones and tablets, where display quality is crucial for user experience.

- Laptops and Monitors: These adhesives enhance the performance of laptops and monitors, making them ideal for professional graphics work.

Automotive Displays

- Dashboard Displays: Optical bonding adhesives are used in automotive dashboards to improve visibility and reduce reflections in varying lighting conditions.

- Infotainment Systems:These systems benefit from enhanced clarity and durability, essential for navigation and entertainment.

Medical Devices

- Diagnostic Equipment: Optical bonding adhesives with critical display accuracy are vital in medical imaging devices.

- Wearable Health Monitors: The durability and clarity provided by optical bonding enhance the usability of health monitoring devices.

Industrial Applications

- Control Panels: In industrial settings, panels that utilize optical bonding adhesives can withstand harsh environments while providing precise readings.

- POS Systems: Point-of-sale systems benefit from enhanced display performance, improving user interactions.

Types of Optical Bonding Adhesives

Optical bonding adhesives can be categorized based on their composition and application methods.

UV-Curable Adhesives

- Fast Curing: UV-curable adhesives cure quickly when exposed to UV light, making them suitable for high-volume production.

- High Optical Clarity: They offer excellent transparency and are ideal for applications requiring minimal color distortion.

Silicone Adhesives

- Flexibility: Silicone-based optical bonding adhesives provide flexibility, making them suitable for applications where thermal expansion is a concern.

- Moisture Resistance:These moisture-resistant adhesives are ideal for outdoor applications.

Epoxy Adhesives

- High Strength: Epoxy adhesives provide superior adhesion strength and are used in applications requiring robust bonding.

- Thermal Stability: These adhesives can withstand high temperatures, making them suitable for industrial applications.

The Optical Bonding Process

Optical bonding involves several steps to ensure optimal adhesion and performance.

Surface Preparation

- Proper surface preparation is crucial for adequate bonding. This involves cleaning the surfaces to remove dust, grease, and other contaminants that could affect adhesion.

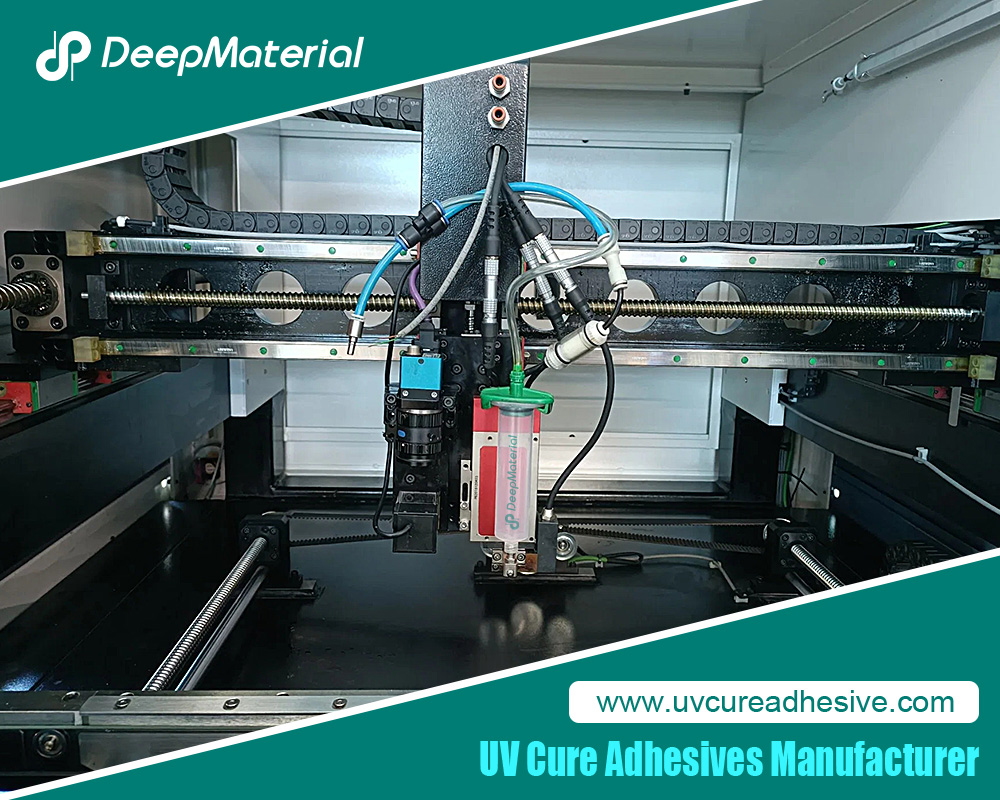

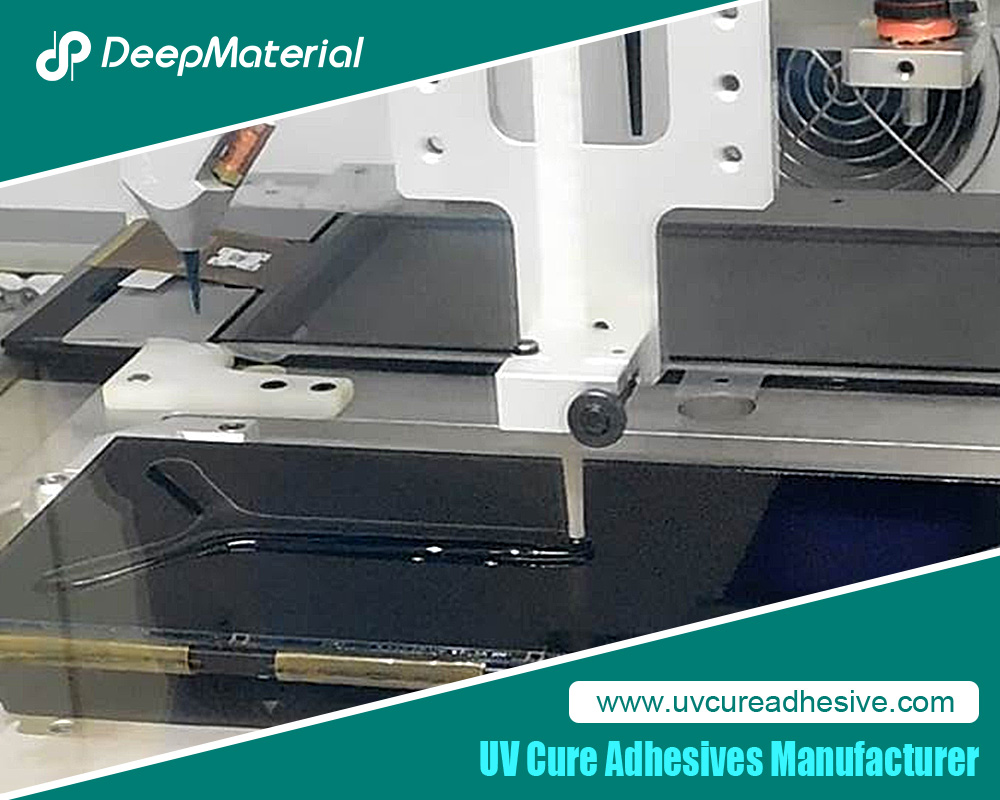

Application of Adhesive

- Depending on the adhesive type and application requirements, various methods, including screen printing, spraying, or dispensing, can be used to apply it.

Curing

- Curing is the process by which the adhesive hardens. Depending on the adhesive used, this can be achieved through heat, UV light, or a combination of both.

Quality Control

- After curing, quality control measures are implemented to ensure the bond is strong and the display meets optical standards. This may involve tests for adhesion strength, clarity, and durability.

Challenges in Optical Bonding

While optical bonding adhesives offer numerous advantages, there are also challenges that manufacturers must consider.

Material Compatibility

- Not all materials are compatible with every type of adhesive, which can lead to issues during the bonding process. Manufacturers must select adhesives that work well with the specific materials being used.

Process Control

- Maintaining consistent process parameters is critical to achieving optimal bonding results. Variations in temperature, humidity, or adhesive application can affect the quality of the bond.

Cost Considerations

- While optical bonding provides long-term savings, the initial investment in equipment and materials can be substantial, particularly for smaller manufacturers.

Future Trends in Optical Bonding Adhesives

As technology continues to evolve, so will the development and application of optical bonding adhesives. Several trends are emerging in this field.

Advances in Material Science

- New Formulations: Ongoing research is leading to the development of new adhesive formulations that offer improved performance and versatility.

- Eco-Friendly Options: There is a growing demand for environmentally friendly adhesives that minimize the environmental impact of manufacturing processes.

Increased Automation

- Automation of the Bonding Process: Automating the optical bonding process will enhance efficiency and reduce the potential for human error.

- Real-Time Monitoring:Implementing real-time monitoring systems will allow manufacturers to track the bonding process closely and ensure quality control.

Integration with Emerging Technologies

- Flexible Displays:The rise of flexible display technologies will necessitate the development of new optical bonding solutions that accommodate flexibility without compromising performance.

- Augmented and Virtual Reality:The demand for high-performance displays in AR and VR applications will drive advancements in optical bonding techniques.

Conclusion

Optical bonding adhesive plays a pivotal role in enhancing the quality and durability of modern displays. From consumer electronics to automotive applications, the benefits of using optical bonding adhesive are numerous, offering improved clarity, increased durability, and cost-effectiveness. As technology advances, the development of new materials and processes will further enhance the capabilities of optical bonding adhesives, solidifying their place as a crucial component in the future of display technology. Embracing these innovations will improve product performance and pave the way for exciting new applications across various industries.

For more about understanding optical bonding adhesive: a comprehensive overview, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.