Potting Compound vs Epoxy: A Comparative Study and Application Overview

In the modern industrial and electronic domains, the selection of materials holds a pivotal position in determining the performance, reliability, and longevity of products. Potting Compound and Epoxy are two frequently encountered materials that each demonstrate remarkable capabilities in numerous applications, yet they possess distinct attributes and application scopes.

Characteristics and Applications of Potting Compound

Potting Compound is a material employed for encapsulating and safeguarding electronic components, electrical apparatuses, and other delicate parts. It typically exhibits the following traits:

- Exceptional insulation performance

It effectively insulates electrical currents and prevents leakage, furnishing reliable electrical insulation protection for electronic components. This feature is particularly crucial in applications where high voltages and precise electrical insulation are demanded.

- Outstanding thermal stability

It can endure extreme high-temperature environments and maintain stable performance within the specified operating temperature range. This characteristic is vital to prevent material degradation caused by temperature fluctuations, ensuring the consistent operation of the encapsulated components.

- Robust chemical stability

It demonstrates strong resistance against acids, alkalis, salts, and other chemical substances, thereby minimizing the risk of chemical corrosion. This makes it suitable for applications where exposure to various chemical agents is inevitable.

- Excellent shock absorption and impact resistance

It has the ability to absorb and buffer external mechanical shock and vibration. This property is highly valuable in protecting internal components from damage, especially in environments prone to mechanical disturbances.

Due to these distinctive characteristics, Potting Compound finds extensive application in the following areas:

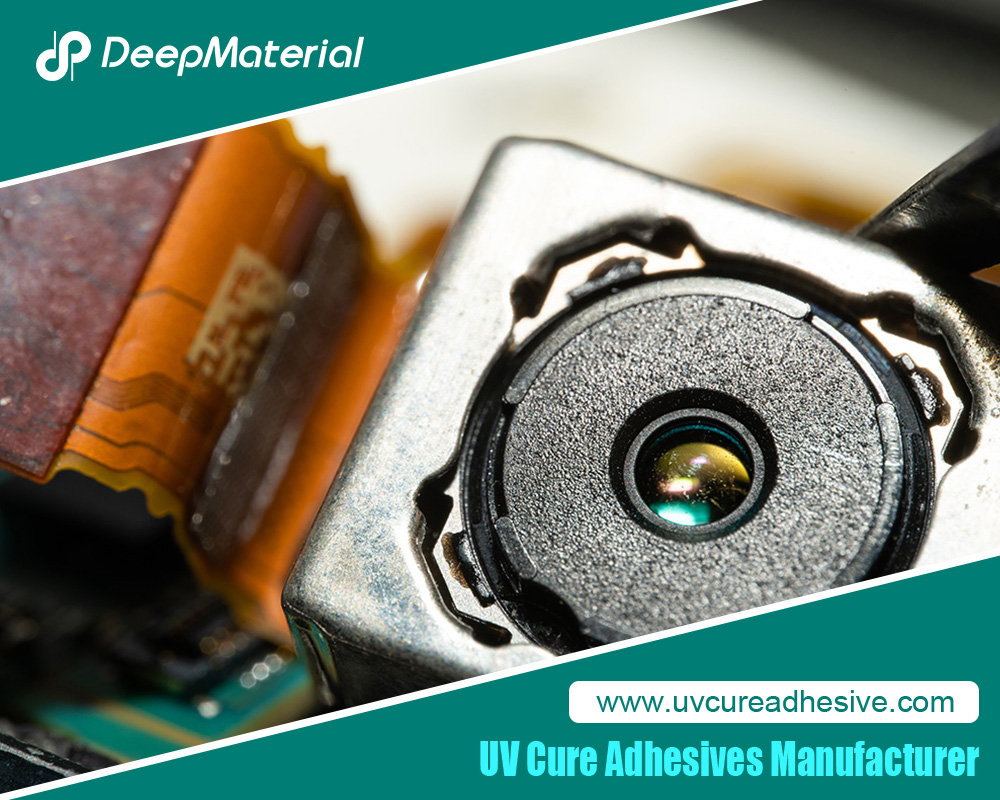

- Electronic devices

It is commonly utilized in power modules, controllers, sensors, and other such components. It provides effective protection against moisture, dust, and vibration, thereby enhancing the lifespan and performance of these electronic devices.

- Automotive electronics

It plays a crucial role in automotive engine control units, sensors, on-board chargers, and other critical components. This helps improve their reliability and durability, especially in the harsh and dynamic conditions of a vehicle’s operation.

- Industrial control

In industrial automation equipment, frequency converters, switch cabinets, and other electrical systems, Potting Compound ensures the stable and uninterrupted operation by protecting the sensitive components from various environmental and operational stresses.

Characteristics and Applications of Epoxy

Epoxy is a type of thermosetting resin that comes with several notable features:

- High mechanical strength

Upon curing, it acquires a high mechanical strength, enabling it to withstand significant loads. This makes it suitable for applications where structural integrity and mechanical robustness are essential.

- Excellent bonding performance

It exhibits a remarkable ability to adhere to a wide range of materials, including metals, plastics, ceramics, and more. This property makes it an ideal choice for bonding applications in various industries.

- Superior corrosion resistance

It can effectively resist the erosion of a diverse array of chemical media, making it suitable for use in harsh chemical environments where other materials might fail.

- High dimensional stability

After curing, the dimensional changes are minimal, ensuring the precision and stability of the final product. This is crucial in applications where tight tolerances and consistent dimensions are required.

Epoxy is widely employed in the following fields:

- Adhesives

It is extensively used as an adhesive for bonding materials such as metals, woods, and glasses. Its high strength and durability make it a preferred choice for many bonding applications.

- Coatings

It provides excellent protection and decorative properties and is frequently utilized for anti-corrosion and coating purposes on metal surfaces. This helps to enhance the appearance and longevity of the coated objects.

- Composites

When combined with fiber materials, it forms high-strength composites, such as carbon fiber-reinforced epoxy composites. These composites find applications in aerospace, automotive, and other industries where lightweight and high-strength materials are needed.

4. Electronic packaging

It plays a significant role in electronic chip packaging and circuit board protection, providing electrical insulation and mechanical support.

Performance Comparison between Potting Compound and Epoxy

- Insulation performance

Potting Compound typically offers superior insulation performance, especially in high-voltage and high-frequency applications. Epoxy also provides good insulation, but in some extremely demanding conditions, it may not match the performance of Potting Compound.

- Thermal performance

The thermal conductivity and thermal expansion coefficient of Potting Compound are often optimized to handle temperature variations more effectively. Epoxy’s thermal performance can be tailored through formulation adjustments, but in high-temperature scenarios, Potting Compound generally demonstrates better stability.

- Mechanical performance

Epoxy typically achieves higher mechanical strength after curing. However, Potting Compound focuses more on shock absorption and impact resistance, which is essential in applications subject to dynamic mechanical forces.

- Cost

In general, Epoxy tends to be relatively more cost-effective. However, the specific price depends on the quality and performance requirements. Potting Compound, due to its specialized formulation and properties, may have a slightly higher cost.

Choosing Potting Compound or Epoxy

The decision between Potting Compound and Epoxy in practical applications is influenced by several factors:

- Application environment

If the equipment is expected to operate in harsh conditions characterized by high temperatures, high humidity, and intense vibration, Potting Compound is often the preferred choice. Conversely, if the environment is relatively mild and less demanding, Epoxy may suffice.

- Performance requirements

For applications with stringent requirements regarding insulation performance, thermal stability, mechanical strength, and other specific parameters, a detailed assessment of the performance capabilities of both materials is necessary to make an informed selection.

- Cost considerations

While meeting the performance criteria, cost becomes a significant factor. If budget constraints are a concern and the performance requirements are not overly demanding, Epoxy may present a more economical option. However, in cases where top-notch performance and reliability are non-negotiable, the slightly higher cost of Potting Compound may be justified.

- Process requirements

The processing methods and characteristics of each material vary. Different materials may have specific curing times, mixing ratios, and application methods. The choice should also take into account the ease and feasibility of the production process.

Future Development Trends

As technology continues to advance, both Potting Compound and Epoxy are undergoing continuous evolution and innovation. The future directions of these materials may include:

- Enhanced performance

To meet the increasingly demanding application requirements, both materials will likely see improvements in insulation strength, thermal stability, mechanical performance, and other aspects. This will enable them to handle more extreme and complex operating conditions.

- Environmental friendliness

With growing environmental consciousness, there will be a greater emphasis on developing materials with reduced volatile organic compound (VOC) emissions, recyclability, and other eco-friendly features.

- Multi-functional integration

Rather than having single-purpose properties, materials of the future are expected to integrate multiple functions. For instance, they may simultaneously offer insulation, heat dissipation, flame retardancy, and other capabilities to meet the diverse needs of modern applications.

Conclusion

Both Potting Compound and Epoxy are important materials and play irreplaceable roles in their respective fields. When choosing, the application requirements, performance requirements, cost, and process should be fully considered to make the most appropriate decision. At the same time, paying attention to the development trends of materials and constantly exploring and applying new technologies and products will help promote the development and progress of related industries.

For more about choosing a comprehensive guide to potting compound vs epoxy: a comparative study and application overview, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.