Exploring Potting Compound for Electronics: The Key Material for Providing Reliable Protection to Electronic Products

In the current era of rapid technological development, electronic products have become an indispensable part of our lives. From smartphones, tablets to smart home devices and industrial control systems, the performance and reliability of electronic devices are crucial for our daily life and work. Among the many factors ensuring the stable operation of electronic products, there is a kind of material playing a vital role, that is, potting compound for electronics.

The potting compound for electronics is a special material used for encapsulating and protecting electronic components, circuits, and devices. It can provide multiple functions such as waterproofing, dustproofing, shockproofing, insulation, heat dissipation, etc., thereby significantly improving the reliability and service life of electronic products.

Classification of Potting Compound for Electronics

There are numerous types of potting compound for electronics. Based on their chemical composition and performance characteristics, they can be roughly classified into the following categories:

Silicone potting compound

Silicone potting compound is currently the most widely used type of potting compound. It has excellent high and low-temperature resistance, weather resistance, electrical insulation, and chemical stability. Silicone potting compound has good flexibility and can effectively alleviate the impact of temperature changes and mechanical vibrations on electronic components. In addition, it also has good gas permeability, which is conducive to the heat dissipation of electronic components.

Epoxy resin potting compound

Epoxy resin potting compound has high strength, high hardness, chemical corrosion resistance, and excellent bonding performance. It can provide good mechanical protection and sealing effects and is suitable for electronic products with high requirements for structural strength. However, the temperature resistance of epoxy resin potting compound is relatively poor and may crack in high-temperature environments.

Polyurethane potting compound

Polyurethane potting compound has good elasticity, wear resistance, and impact resistance. Its bonding performance is also outstanding and can firmly bond with various materials. Polyurethane potting compound can still maintain good performance in low-temperature environments and is suitable for some electronic products with requirements for cold resistance.

Acrylate potting compound

Acrylate potting compound has a fast curing speed, good transparency, and weather resistance. It can cure quickly at room temperature and is suitable for some electronic products that require rapid production. However, the temperature resistance and chemical corrosion resistance of acrylate potting compound are relatively weak.

Performance Characteristics of Potting Compound for Electronics

Waterproof and Dustproof

Electronic products are often exposed to various harsh environments during use, such as humid and dusty environments. The potting compound for electronics can form a sealed protective layer, effectively preventing water and dust from entering the interior of electronic components, thereby avoiding short circuits, corrosion, and other problems.

Shock and Impact Resistance

Electronic devices may be subject to vibration and shock during transportation and use. The elasticity and flexibility of the potting compound can absorb and disperse this energy, reducing damage to electronic components and improving the stability and reliability of the equipment.

Insulation and Heat Dissipation

The potting compound for electronics has good electrical insulation performance, which can ensure electrical isolation between electronic components and prevent leakage and short circuits. At the same time, the potting compound can also help electronic components dissipate heat, reduce the working temperature, and extend their service life.

Chemical Corrosion Resistance

Electronic products may come into contact with various chemical substances, such as acids, alkalis, salts, etc. The potting compound for electronics can resist the erosion of these chemical substances and protect electronic components from damage.

High and Low Temperature Resistance

Electronic devices may experience extreme temperature changes during operation. High-quality potting compound for electronics should be able to maintain stable performance within a wide temperature range to ensure the normal operation of electronic components.

Application Fields of Potting Compound for Electronics

Consumer Electronics Field

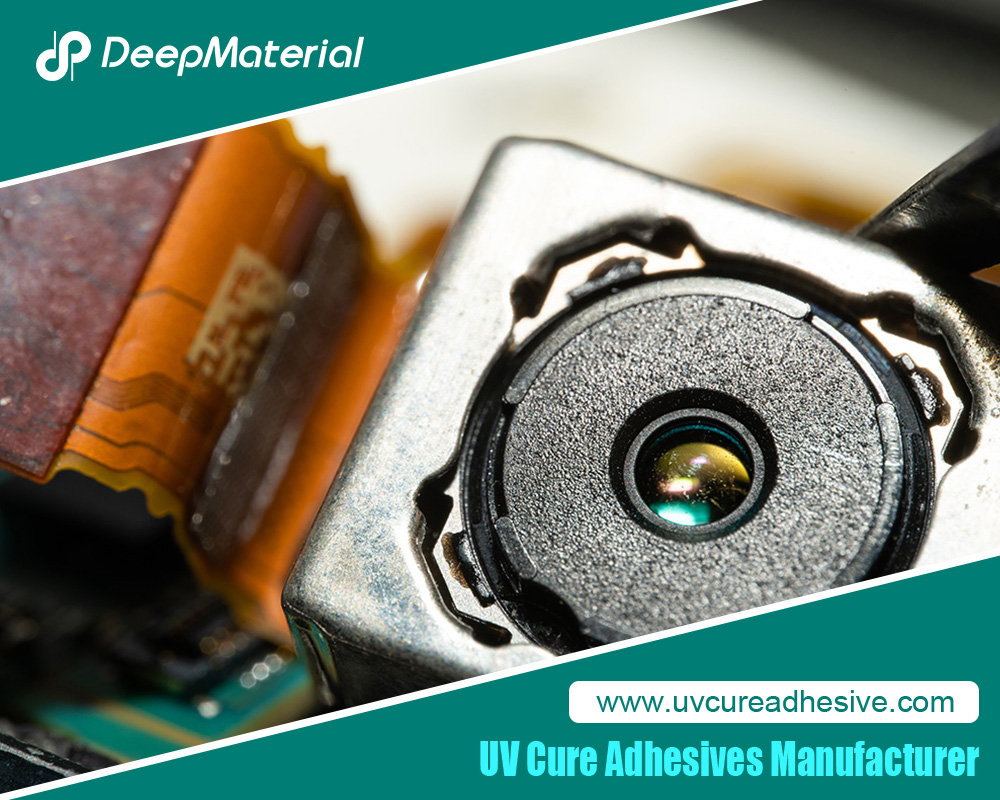

In consumer electronic products such as smartphones, tablets, laptops, etc., potting compound for electronics is widely used to protect key components such as batteries, circuit boards, camera modules, etc. For example, in battery packaging, the potting compound can prevent battery short circuits and improve the safety and stability of the battery; in circuit board packaging, the potting compound can protect electronic components from the influence of the external environment and improve the reliability of the product.

Automotive Electronics Field

The working environment of automotive electronic systems is complex, and the reliability requirements for electronic components are extremely high. The application of potting compound for electronics in the automotive electronics field includes engine control modules, on-board chargers, sensors, etc. The potting compound can withstand vibration, high temperature, and chemical corrosion during vehicle driving to ensure the stable operation of automotive electronic systems.

Industrial Electronics Field

In industrial electronic fields such as industrial control systems, power equipment, and automation equipment, potting compound for electronics is used to protect sensitive electronic components and circuits. For example, in frequency converters, switch cabinets, and other equipment, the potting compound can improve the protection level of the equipment and prevent electrical failures.

New Energy Field

With the rapid development of the new energy industry, potting compound for electronics has also been widely applied in solar photovoltaic, wind power generation, energy storage systems, and other fields. In solar photovoltaic modules, the potting compound can protect battery cells and junction boxes and improve the service life and reliability of the modules; in energy storage systems, the potting compound can protect battery modules and improve the safety and stability of the system.

Selection and Use of Potting Compound for Electronics

Select the Appropriate Potting Compound

When selecting potting compound for electronics, the following factors need to be considered based on specific application requirements:

– The working environment of electronic components, including temperature, humidity, chemical substances, etc.;

– The performance characteristics of the potting compound, such as high and low temperature resistance, insulation performance, bonding performance, etc.;

– The potting process requirements, such as curing time, viscosity, etc.;

– Cost factors.

Potting Process

The potting process of potting compound for electronics usually includes the following steps:

– Preparation: Clean and dry the electronic components to ensure the surface is free of oil, dust, and other impurities.

– Mix the adhesive: Accurately measure and mix the A and B components of the potting compound according to the product manual. During the mixing process, pay attention to uniform stirring to avoid the generation of bubbles.

– Potting operation: Slowly pour the mixed potting compound into the electronic components to be encapsulated to ensure the glue fills the entire space and avoids voids.

– Curing treatment: Select the appropriate curing method based on the curing conditions of the potting compound, such as room temperature curing, heating curing, etc. During the curing process, pay attention to maintaining a clean and stable environment.

Development Trends of Potting Compound for Electronics

High Performance

With the continuous upgrading of electronic products and the expansion of application fields, the performance requirements for potting compound for electronics are also getting higher and higher. In the future, potting compound for electronics will develop in the direction of higher temperature resistance, better insulation performance, stronger chemical corrosion resistance, etc.

Environmental Friendliness

The increasing awareness of environmental protection prompts potting compound for electronics to develop in the direction of solvent-free and low volatile organic compound (VOC) emissions. At the same time, recyclable and degradable potting compounds will also become a research hotspot.

Multi-functionality

To meet the increasingly complex functional requirements of electronic products, potting compound for electronics will have more functions, such as heat conduction, electrical conductivity, electromagnetic shielding, etc.

Customization

Different electronic products have different performance and process requirements for potting compound. In the future, potting compound suppliers will provide more customized solutions to meet the individualized needs of customers.

Conclusion

As an indispensable part of electronic products, the performance and quality of potting compound for electronics directly affect the reliability and service life of electronic products. With the continuous progress of technology and the changing market demands, potting compound for electronics is also constantly developing and innovating. It is believed that in the future, potting compound for electronics will provide stronger support and guarantee for the development of the electronics industry.

For more about choosing a comprehensive guide to exploring potting compound for electronics: the key material for providing reliable protection to electronic products, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.