The Evolving Landscape of the Display Module Adhesives Market

In the rapidly advancing world of electronics, display module adhesives are critical to ensuring device performance and longevity. These adhesives bond display screens to their enclosures, contributing to electronic devices’ overall durability and aesthetic appeal. As display technology evolves, the need for advanced adhesive solutions has never been more pronounced, driving innovation in the display module adhesives market.

Critical Characteristics of Effective Display Module Adhesives

For adhesives used in display modules, specific characteristics are vital for their performance:

- Optical Clarity: Ensuring that the adhesive does not impede the display’s visual quality.

- Thermal Stability: Capable of withstanding temperature fluctuations without degrading.

- Mechanical Strength: Providing reliable bonding that can endure stress and impact.

- Chemical Resistance: Able to resist various environmental factors, including humidity and chemical exposure.

These characteristics are essential for maintaining the integrity and functionality of electronic displays.

Classification of Adhesive Types in the Market

The display module adhesives market encompasses various types of adhesives, each tailored to meet specific requirements:

- Epoxy Adhesives: Epoxy Adhesives are ideal for high-performance applications because they are known for their exceptional strength and resistance to heat and chemicals.

- Acrylic Adhesives:Acrylic Adhesives Offer superior transparency and UV resistance, and they are often used in consumer electronics for their aesthetic qualities.

- Silicone Adhesives:Silicone adhesives provide flexibility and thermal stability, making them well-suited for applications that require some movement or expansion.

This diversity in adhesive types enables manufacturers to choose the most suitable solution.

Driving Forces Behind Market Expansion

The display module adhesives market is experiencing substantial growth due to several driving forces:

The Impact of Technological Innovations on Adhesive Solutions

- Continuous advancements in adhesive formulations are leading to improved performance characteristics. Innovations such as nanotechnology and intelligent adhesives pave the way for products that can adapt to varying conditions and enhance device functionality.

Consumer Electronics: A Primary Application Area

- The proliferation of smartphones, tablets, and other consumer electronics has created a robust demand for high-quality display modules. Consumers increasingly expect superior display performance, so manufacturers are investing in advanced adhesive technologies to meet these demands.

Challenges Facing the Display Module Adhesives Industry

Despite the growth opportunities, the display module adhesives market faces significant challenges that manufacturers must navigate.

The Importance of Regulatory Compliance

- Manufacturers are required to comply with complex regulations regarding the use of chemicals in adhesives. Compliance with environmental laws, such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances), is essential for maintaining market viability but can be cumbersome.

Market Dynamics: Competition and Price Sensitivity

The display module adhesives market is highly competitive, with numerous players vying for market share. Consumer price sensitivity can lead to aggressive pricing strategies, affecting manufacturers’ profit margins.

Future Prospects and Emerging Trends in Adhesives

The future of the display module adhesives market is marked by several emerging trends shaping its trajectory.

The Shift Towards Eco-Friendly Adhesive Solutions

- As sustainability becomes increasingly important, there is a growing emphasis on developing eco-friendly adhesives. Manufacturers are exploring bio-based and low-VOC (volatile organic compounds) formulations to minimize environmental impact.

Integrating Adhesives with Advanced Display Features

The display module adhesives market is evolving rapidly in response to the increasing complexity of modern devices, particularly with the rise of intelligent technology. As manufacturers seek to develop advanced display features, adhesives must adapt to support functionalities such as touch sensitivity and flexible displays. This integration is essential for ensuring optimal performance and user experience. Key considerations in this shift include:

- Touch Sensitivity: Adhesives must enable accurate touch response without interfering with the functionality of capacitive touch screens, which are prevalent in smartphones and tablets.

- Flexible Displays:The growing demand for flexible and curved displays requires adhesives that can maintain their properties while allowing for bending and movement without losing adhesion strength.

- Durability Under Stress: Adhesives must withstand the mechanical stress and environmental factors encountered in wearable technology, ensuring long-term performance without delamination or failure.

- Optical Clarity: The adhesive should not compromise the display’s visual quality, maintaining high levels of transparency and minimizing light distortion.

- Chemical Resistance: With the increasing prevalence of devices that may come into contact with various substances, adhesives must demonstrate resistance to chemicals, moisture, and extreme temperatures.

Regional Insights: Analyzing Market Growth by Area

The display module adhesives market exhibits varying growth rates across regions, influenced by local consumer behavior, technological advancements, and economic conditions.

North America: A Leader in Adhesive Technology

- North America remains a stronghold for technological innovation, driven by a high demand for consumer electronics and a robust research and development landscape. The region’s focus on advanced manufacturing techniques fosters continuous improvements in adhesive formulations.

Asia-Pacific: The Heart of Consumer Electronics Production

- The Asia-Pacific region dominates the display module adhesives market, led by countries like China and Japan. The increasing production of consumer electronics and advancements in display technologies create a significant demand for specialized adhesive solutions.

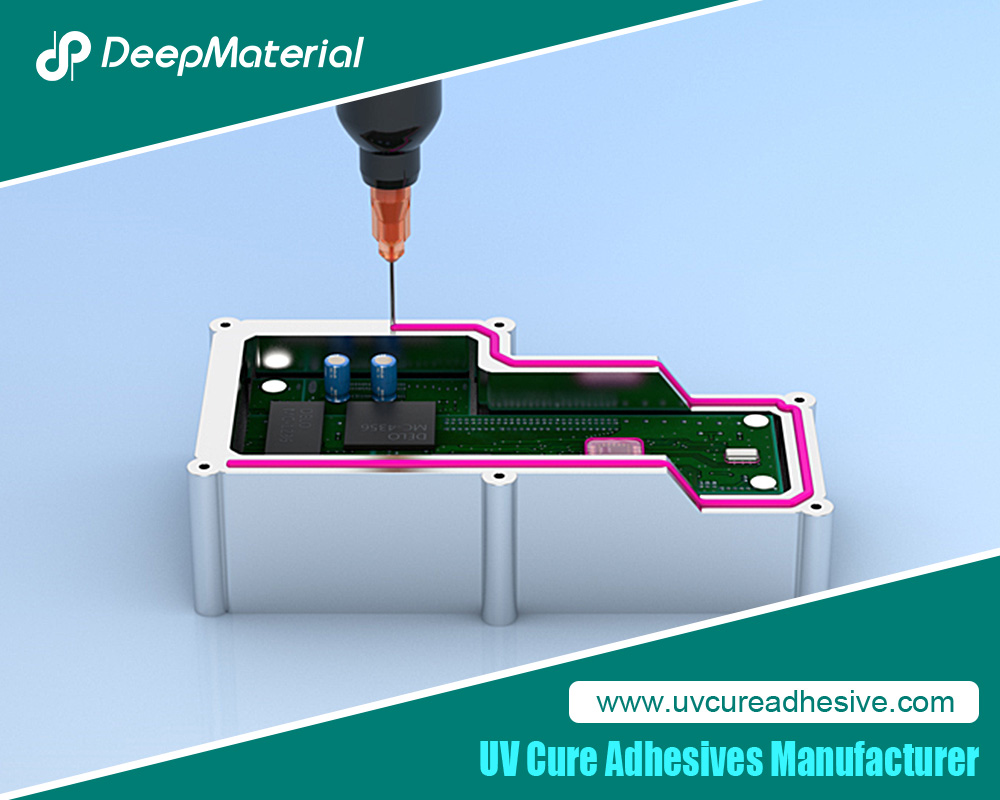

The Role of Automation in Adhesive Application Processes

The display module adhesives market is witnessing a significant transformation due to the integration of automation in adhesive application processes. As manufacturing facilities adopt advanced technologies, the application of adhesives is becoming more precise and efficient. Innovations in dispensing systems are at the forefront of this evolution, offering numerous advantages that enhance the overall production process. These technological advancements streamline operations and contribute to higher-quality end products. Key benefits of automation in adhesive applications include:

- Enhanced Precision: Automated dispensing technologies ensure adhesives are applied uniformly and accurately, minimizing product performance variations.

- Increased Efficiency: Automation reduces the time taken for adhesive application, allowing manufacturers to increase production speeds and meet rising demand in the display module adhesives market.

- Waste Reduction: Automated systems significantly reduce material waste by controlling the amount of adhesive used, leading to cost savings and more sustainable manufacturing practices.

- Consistency Across Batches: Automation provides manufacturers with the ability to maintain consistent performance and quality across different production batches, which is critical in industries where quality assurance is paramount.

- Data-Driven Insights: Automated systems can collect and analyze data on adhesive application processes, enabling manufacturers to optimize operations and identify areas for improvement.

Conclusion

The display module adhesives market is poised for substantial growth, driven by technological advancements, increasing demand for display technologies, and expanding applications across various industries. While challenges such as regulatory compliance and market competition exist, the future holds promising opportunities, particularly in sustainable and intelligent adhesive solutions. By staying attuned to emerging trends and overcoming challenges, stakeholders can strategically position themselves to capitalize on the evolving landscape of the display module adhesives market, ensuring they remain competitive in this vital industry. As technology advances, adhesives’ role will become even more critical in shaping the future of electronic displays.

For more about choosing the evolving landscape of the display module adhesives market, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.