The Best UV Lights for Curing Glue: A Comprehensive Guide

Ultraviolet (UV) light has become essential in various industries, especially in adhesives and bonding. UV light is widely used to cure glue, making it a popular choice for tasks requiring quick and reliable bonding. However, choosing the right UV light can be challenging, given the variety of options available. This article will guide you through the best UV lights for curing glue, exploring their features, benefits, and applications.

Understanding UV Light for Curing Glue

UV light is a type of electromagnetic radiation with a wavelength shorter than visible light but longer than X-rays. Based on wavelength, UV light is divided into different types, including UV-A, UV-B, and UV-C. UV-A light is commonly used to cure glue due to its effectiveness in initiating the polymerization process in UV-sensitive adhesives.

How UV Light Cures Glue

UV-curable adhesives contain photosensitive components that react to UV light. When exposed to UV light, these adhesives undergo a chemical reaction that causes them to harden or cure. This process provides a strong and durable bond, making UV-curable adhesives suitable for various applications, from woodworking to electronics.

Key Features to Look For in UV Lights for Curing Glue

Several factors should be considered when selecting a UV light for curing glue to ensure optimal performance and efficiency. Here are the key features to look for:

Wavelength Range

The effectiveness of UV light for curing glue largely depends on its wavelength range. UV lights designed for curing adhesives typically operate in the UV-A spectrum, with wavelengths between 320 and 400 nanometers (nm). Ensure your UV light falls within this range to achieve the best curing results.

Intensity and Output

The intensity and output of a UV light determine how quickly and effectively it can cure the adhesive. Higher-intensity UV lights can cure glue faster, which is beneficial for high-volume applications. Look for UV lights with adjustable intensity settings to accommodate different curing needs.

Coverage Area

The coverage area of a UV light is crucial, especially for larger projects. UV lights come in various sizes and configurations, including handheld devices, lamps, and curing stations. Choose a UV light that provides adequate coverage for your application to ensure even and complete curing.

Safety Features

UV light can harm the skin and eyes, so safety features are essential. Look for UV lights with built-in safety features such as automatic shut-off timers, protective covers, and UV-blocking glasses. Additionally, consider UV lights that comply with safety standards and regulations.

Durability and Build Quality

UV lights are often used in demanding environments, so durability is essential. Choose UV lights made from high-quality materials that can withstand regular use and resist damage from UV exposure. Consider factors such as heat resistance, impact resistance, and ease of maintenance.

Top UV Lights for Curing Glue

Here are some of the best UV lights for curing glue available on the market:

**1. UV LED Curing Light by LUMICure

Features:

- Wavelength: 365 nm

- Intensity: Adjustable settings

- Coverage Area: Large curing area

- Safety: Built-in UV-blocking glass

Overview: The UV LED Curing Light by LUMICure is a versatile and robust option for curing glue. Its adjustable intensity settings and large curing area make it suitable for various applications, including woodworking and electronics. The built-in UV-blocking glass ensures safety during use.

**2. Heraeus Noblelight UV Curing System

Features:

- Wavelength: 395 nm

- Intensity: High-intensity output

- Coverage Area: Customizable sizes

- Safety: Automatic shut-off timer

Overview: The Heraeus Noblelight UV Curing System is known for its high-intensity output and customizable coverage area. It is ideal for industrial applications where fast and efficient curing is required. The automatic shut-off timer adds an extra layer of safety for users.

**3. Xenon UV Curing Lamp by Nordson

Features:

- Wavelength: 320-400 nm

- Intensity: Variable settings

- Coverage Area: Adjustable

- Safety: UV-blocking protective cover

Overview: The Xenon UV Curing Lamp by Nordson offers variable intensity settings and adjustable coverage areas, making it suitable for small and large projects. Its UV-blocking protective cover enhances user safety, while its versatile design caters to various curing needs.

**4. UV LED Curing Light by ELEGOO

Features:

- Wavelength: 405 nm

- Intensity: Fixed output

- Coverage Area: Compact design

- Safety: UV-blocking glasses included

Overview: The UV LED Curing Light by ELEGOO is a compact and efficient option for smaller projects. Its fixed output provides consistent curing performance, and the included UV-blocking glasses ensure user safety. This UV light is ideal for hobbyists and small-scale applications.

**5. UV Curing Chamber by UV Process Supply

Features:

- Wavelength: 365 nm

- Intensity: High-intensity UV-A

- Coverage Area: Large chamber

- Safety: Fully enclosed design

Overview: The UV Curing Chamber by UV Process Supply is a high-performance option for large-scale applications. Its fully enclosed design provides maximum safety, while its high-intensity UV-A light ensures rapid and effective curing of adhesives.

Applications and Benefits of UV Curing Lights

UV curing lights are used in various industries for different applications. Here are some common uses and benefits:

**1. Woodworking and Furniture

UV-curable adhesives are widely used in woodworking and furniture manufacturing. They provide a strong bond that is resistant to moisture and temperature changes. UV lights ensure quick and reliable curing, reducing production time and increasing efficiency.

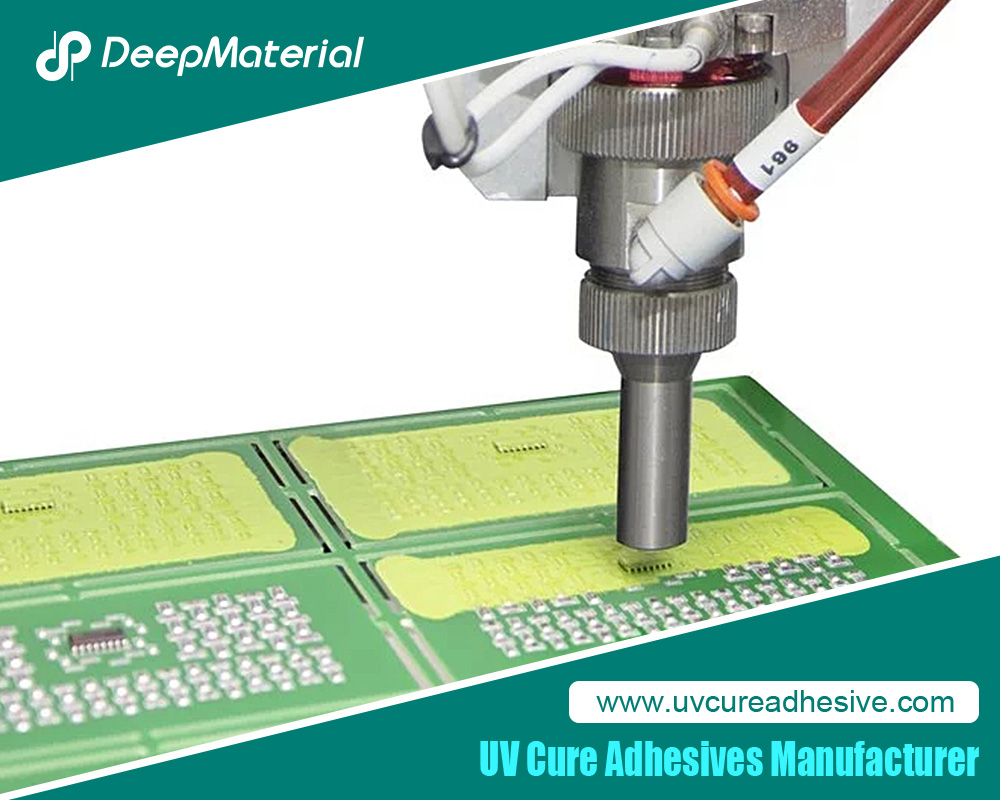

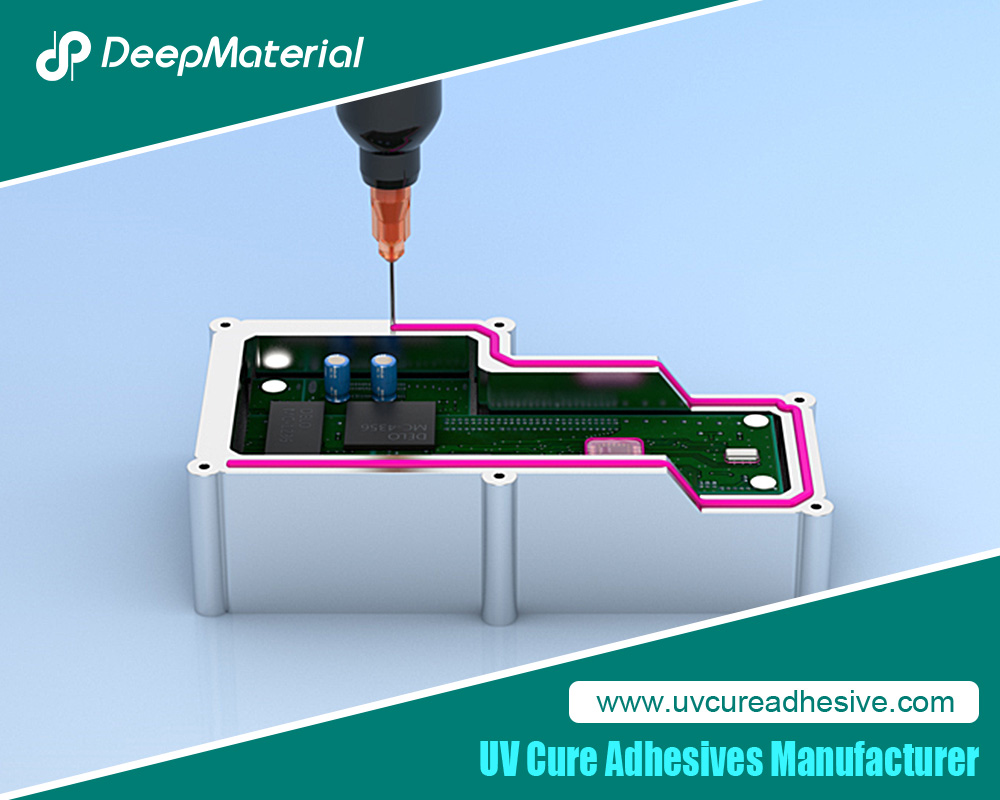

**2. Electronics and Electrical Components

In the electronics industry, UV-curable adhesives bond components and encapsulate electronic parts. UV curing lights offer precise and controlled curing, which is essential for maintaining electronic device integrity and preventing damage.

**3. Automotive Industry

The automotive industry uses UV-curable adhesives for various applications, including windshield bonding and interior trim attachment. UV curing lights enable fast curing, reducing vehicle assembly time and improving overall quality.

**4. Medical and Healthcare

UV-curable adhesives are used to manufacture medical devices and equipment in the medical and healthcare sectors. UV curing lights provide a clean and efficient process, ensuring the reliability and safety of medical products.

Conclusion

Choosing the best UV light for curing glue depends on several factors: wavelength, intensity, coverage area, safety features, and durability. By considering these factors and exploring the top UV lights available, you can find the ideal UV light for your specific needs. Investing in a high-quality UV curing light will enhance your efficiency and ensure reliable bonding, whether you are involved in woodworking, electronics, automotive, or medical applications.

For those seeking the best UV light for curing glue, options such as the LUMICure UV LED Curing Light, Heraeus Noblelight UV Curing System, and Xenon UV Curing Lamp by Nordson offer exceptional performance and safety features. By selecting the proper UV light, you can achieve optimal curing results and enhance your productivity in various industries.

For more about choosing the best UV lights for curing glue: a comprehensive guide, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.