Exploring the Brilliance of UV-Activated Glues: Unveiling the Best Choices

UV-activated glues are innovative adhesive marvels offering rapid bonding and impressive strength. Activated by ultraviolet light, these adhesives have revolutionized various industries, from electronics to medical devices. In this article, we delve into the intricacies of UV-activated glues, exploring their applications, advantages, and the top contenders in the market.

Understanding UV-Activated Glues: UV-activated glues, or UV-curing adhesives, utilize ultraviolet light to initiate polymerization and bond materials together. These adhesives typically consist of monomers, oligomers, photoinitiators, and additives. When exposed to UV light, the photoinitiators within the adhesive undergo a reaction, forming radicals that initiate cross-linking between the monomers and oligomers. This rapid polymerization process produces a robust and durable bond within seconds, making UV-activated glues ideal for applications requiring fast curing times and high bond strength.

Applications of UV-Activated Glues:

The versatility of UV-activated glues makes them suitable for a wide range of applications across various industries:

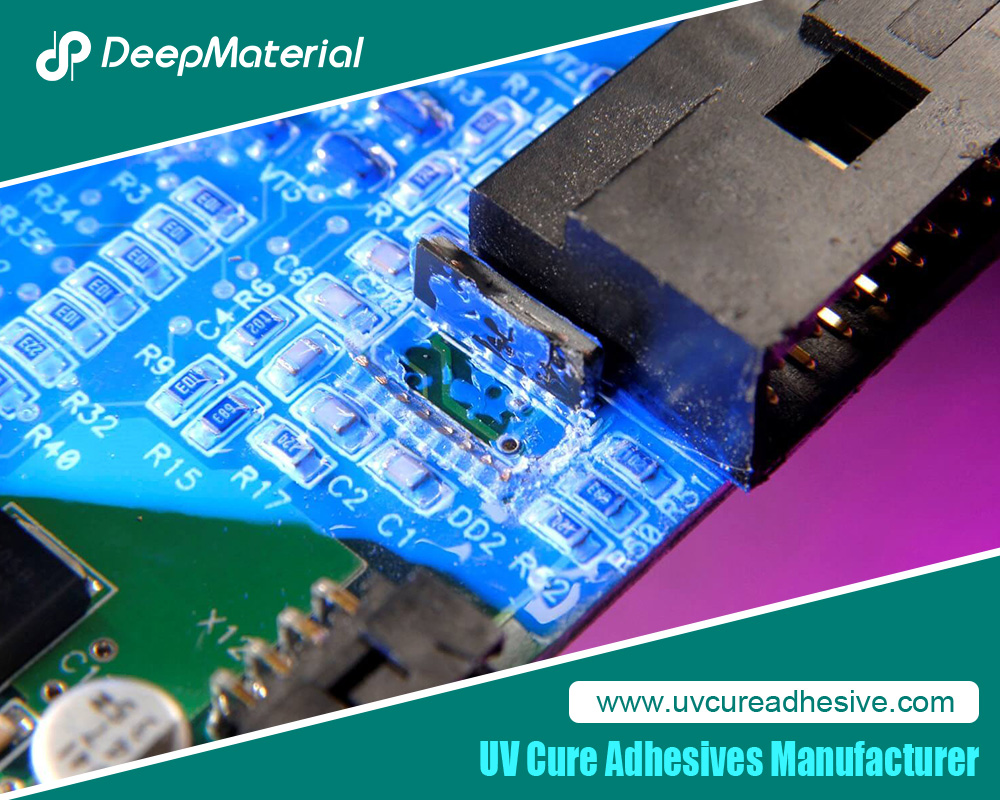

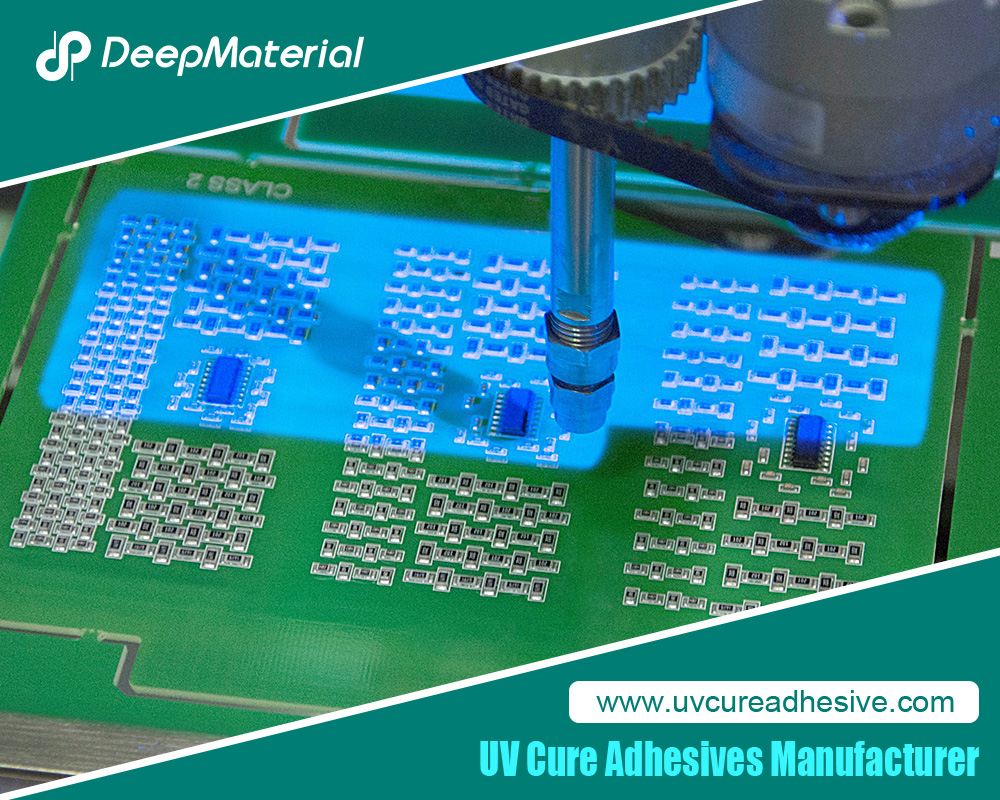

- Electronics: UV adhesives are extensively used in electronics manufacturing for bonding components such as display screens, circuit boards, and microchips. Their rapid curing time and ability to bond different substrates make them indispensable in this sector.

- Medical Devices: UV-activated glues bond medical devices such as catheters, syringes, and surgical instruments. Their biocompatibility and ability to withstand sterilization make them ideal for medical applications.

- Optics: Optical bonding, used in producing lenses, displays, and optical filters, relies on UV-activated adhesives for precise bonding with minimal distortion. These adhesives ensure excellent optical clarity and durability in optical assemblies.

- Automotive: UV adhesives are employed in automotive manufacturing for bonding glass, plastic, and metal components. Their high bond strength and resistance to temperature fluctuations make them suitable for vehicle structural bonding.

Advantages of UV-Activated Glues:

UV-activated glues offer several advantages over traditional adhesives, making them preferred choices in many applications:

- Rapid Curing: One of the most significant advantages of UV adhesives is their fast curing time, often within seconds. This enables efficient production processes and reduces assembly time.

- High Bond Strength: UV-activated glues create strong bonds with excellent adhesion to various substrates, including glass, metal, plastic, and ceramics. The resulting bonds exhibit high tensile and shear strength.

- Precise Application: UV adhesives, thanks to their liquid form, can be applied in exact amounts before curing. This allows for accurate placement and minimizes waste.

- Chemical Resistance: Once cured, UV-activated glues exhibit exceptional resistance to chemicals, solvents, and environmental factors, ensuring long-term durability in various operating conditions.

- Versatility: UV adhesives are compatible with diverse substrates and can be tailored to meet specific application requirements, such as flexibility, hardness, or thermal conductivity.

Top Contenders in the Market:

Several UV-activated glues have gained prominence for their exceptional performance and reliability. Let’s explore some of the top contenders:

- Loctite 3492 UV Epoxy Adhesive: Loctite, a renowned name in the adhesive industry, offers a high-performance UV epoxy adhesive suitable for bonding various materials, including metals, plastics, and glass. It features rapid curing, excellent adhesion, and superior chemical resistance.

- Dymax 9001-M UV Light-Curable Adhesive: Dymax Corporation produces a range of UV-curable adhesives renowned for their versatility and reliability. The Dymax 9001-M adhesive exhibits high bond strength, rapid curing, and excellent clarity, making it ideal for optical bonding and electronic applications.

- Permabond UV632 UV Curable Adhesive: Permabond, a global leader in adhesive technology, offers the UV632 adhesive known for its exceptional bond strength and chemical resistance. This adhesive is suitable for bonding plastics, glass, and metals in various industrial applications.

- Master Bond UV15X-6Med-2 UV Curable Adhesive: Master Bond specializes in high-performance adhesives for demanding applications, including medical devices. The UV15X-6Med-2 adhesive is biocompatible, USP Class VI approved and exhibits excellent bond strength and durability in medical device assembly.

- 3M Scotch-Weld UV Epoxy Adhesive: 3M is synonymous with quality and innovation, and their Scotch-Weld UV Epoxy Adhesive is no exception. This adhesive offers rapid curing, high bond strength, and exceptional durability, making it suitable for various industrial applications, including electronics, aerospace, and automotive.

- Henkel Technomelt UV Light-Curable Adhesive: Henkel, a global leader in adhesive technologies, produces the Technomelt UV Light-Curable Adhesive, which is designed for rapid bonding of heat-sensitive substrates. This adhesive offers excellent adhesion to plastics, metals, and glass, making it ideal for automotive, electronics, and medical applications.

- DELO DUALBOND UV/Thermal-Curable Adhesive: DELO, a German adhesive manufacturer, offers the DUALBOND UV/Thermal-Curable Adhesive, which combines UV and thermal curing mechanisms for enhanced performance. This adhesive provides excellent bond strength, temperature, and chemical resistance, making it suitable for demanding automotive, aerospace, and electronics applications.

- UVITEC UV-Activated Epoxy Resin: UVITEC specializes in UV-activated resins for bonding and coating applications. Their UV-activated epoxy Resin offers rapid curing, high bond strength, and exceptional clarity, making it ideal for optical bonding, electronic encapsulation, and medical device assembly.

These top contenders in the UV-activated adhesive market showcase the industry’s diversity and innovation. A UV adhesive solution is tailored to meet specific requirements and performance standards, whether for electronics, medical devices, optics, automotive, or aerospace applications.

Curing speed, bond strength, chemical resistance, and substrate compatibility are crucial considerations when selecting the appropriate UV-activated adhesive for a particular application. Factors like biocompatibility, regulatory approvals, and environmental concerns may be paramount, especially in medical devices and aerospace industries.

As technology advances and new materials emerge, UV adhesives evolve to meet industries’ evolving needs worldwide. Manufacturers are continually pushing the boundaries of performance, developing adhesives with enhanced properties and capabilities to address the challenges of modern manufacturing processes.

UV-activated glues represent a pinnacle of adhesive technology, offering rapid curing, high bond strength, and versatility across many applications. As industries continue to innovate and demand advanced bonding solutions, UV adhesives will remain indispensable in achieving efficient manufacturing processes and reliable product performance. With top contenders like Loctite, Dymax, Permabond, and Master Bond leading the way, the future of UV-activated glues looks bright, promising continued advancements and new possibilities in bonding technology.

In conclusion, UV-activated adhesives represent a cornerstone of modern bonding technology, offering rapid, reliable, and versatile solutions for a wide range of applications. With leading manufacturers constantly innovating and improving their formulations, the future of UV adhesives looks promising, paving the way for greater efficiency, reliability, and performance across diverse industries.

For more about exploring the brilliance of UV-activated glues: unveiling the best choices, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.