Conformal Coatings Market for Automotive Electronics: An In-Depth Analysis

The automotive industry has witnessed significant technological advancements in recent years, particularly in automotive electronics. These advancements have enhanced vehicle performance and safety and driven the need for adequate protection of electronic components. One of the critical solutions to this challenge is the application of conformal coatings. These specialized coatings protect electronic components from harsh environmental conditions, ensuring their longevity and reliability. This article provides:

- A comprehensive overview of the conformal coatings market for automotive electronics.

- Exploring its growth drivers and key trends.

The Importance of Conformal Coatings in Automotive Electronics

Automotive electronics have become increasingly complex and vital, with components ranging from sensors and control units to infotainment systems and advanced driver-assistance systems (ADAS). These components are often exposed to harsh conditions such as extreme temperatures, moisture, dust, and chemicals. Conformal coatings provide a protective barrier that prevents these elements from damaging the electronic circuitry, enhancing the durability and performance of automotive electronics.

Types of Conformal Coatings

There are several types of conformal coatings used in automotive electronics, each with its own set of properties and applications:

- Acrylic Coatings: These are widely used for their ease of application and removal. They offer good protection against moisture and humidity but may be less effective against chemicals.

- Silicone Coatings: Known for their flexibility and high-temperature resistance, silicone coatings protect components exposed to extreme temperature variations.

- Polyurethane Coatings: These coatings offer excellent chemical resistance and are often used in environments where exposure to harsh chemicals is a concern.

- Epoxy Coatings: Epoxy coatings provide a robust barrier against moisture, chemicals, and physical damage. However, they are less flexible than silicone or polyurethane coatings, making them more suitable for rigid components.

- Parylene Coatings: These coatings are applied through a vapor deposition, resulting in a thin, uniform layer that protects against moisture, chemicals, and temperature extremes.

Applications of Conformal Coatings in Automotive Electronics

Conformal coatings are used in various automotive electronic systems, including:

- Engine Control Units (ECUs): These are the brains of modern vehicles, controlling multiple functions such as fuel injection, ignition timing, and emission control. Conformal coatings protect ECUs from environmental factors that could lead to malfunctions.

- Sensors: Automotive sensors, such as those used in ADAS, require reliable performance in diverse conditions. Conformal coatings ensure that these sensors function accurately by protecting them from moisture and contaminants.

- Infotainment Systems: The growing demand for sophisticated infotainment systems has led to the integrating of sensitive electronic components in the vehicle’s cabin. Conformal coatings protect these components from dust, moisture, and other hazards.

- Battery Management Systems (BMS): In electric vehicles (EVs), the BMS is crucial for monitoring and managing battery performance. Conformal coatings help protect the BMS from temperature fluctuations, moisture, and chemicals, ensuring optimal battery performance and safety.

Market Dynamics

Several factors, including technological advancements, regulatory requirements, and consumer demand for reliable and durable vehicles, influence the conformal coatings market for automotive electronics. This section explores the key market dynamics driving its growth.

Growth Drivers

- Increasing Adoption of Electric Vehicles (EVs): The global shift towards EVs is one of the primary drivers of the conformal coatings market. EVs rely heavily on electronic components for battery management, power control, and charging systems. Protecting these components from environmental factors is boosting the demand for conformal coatings.

- Advancements in ADAS and Autonomous Driving Technologies: The development of ADAS and autonomous driving technologies requires highly reliable electronic systems. Conformal coatings play a critical role in ensuring the performance and longevity of these systems, driving their adoption in the automotive industry.

- Stringent Environmental Regulations: Governments worldwide impose stricter regulations on vehicle emissions and safety standards. This has led to an increased focus on the reliability and durability of automotive electronics, further fueling the demand for conformal coatings.

- Consumer Demand for High-Performance Vehicles: Modern consumers expect high-performance, safe, and comfortable vehicles. This has led to integrating advanced electronic systems in cars, increasing the need for adequate protection through conformal coatings.

Challenges

- High Costs: Conformal coatings can be expensive, particularly for high-performance coatings like parylene. This cost factor can be a barrier for smaller automotive manufacturers and may limit the adoption of these coatings.

- Complex Application Processes: The application of certain conformal coatings, such as perylene, requires specialized equipment and processes. This can increase production time and costs, posing a challenge for manufacturers.

- Environmental Concerns: While conformal coatings protect electronic components, some types of coatings, such as those based on solvents, can have negative ecological impacts. The automotive industry is pressured to adopt more environmentally friendly coatings, which can be challenging regarding cost and performance trade-offs.

- Limited Awareness and Expertise: Not all stakeholders in the automotive industry sometimes fully understand the benefits of conformal coatings. This lack of awareness and expertise can hinder the widespread adoption of these coatings.

Key Trends

- Development of Environmentally Friendly Coatings: There is a growing trend towards developing environmentally friendly conformal coatings in response to environmental concerns. Water-based and bio-based coatings are gaining traction as they offer a lower environmental impact while providing adequate protection.

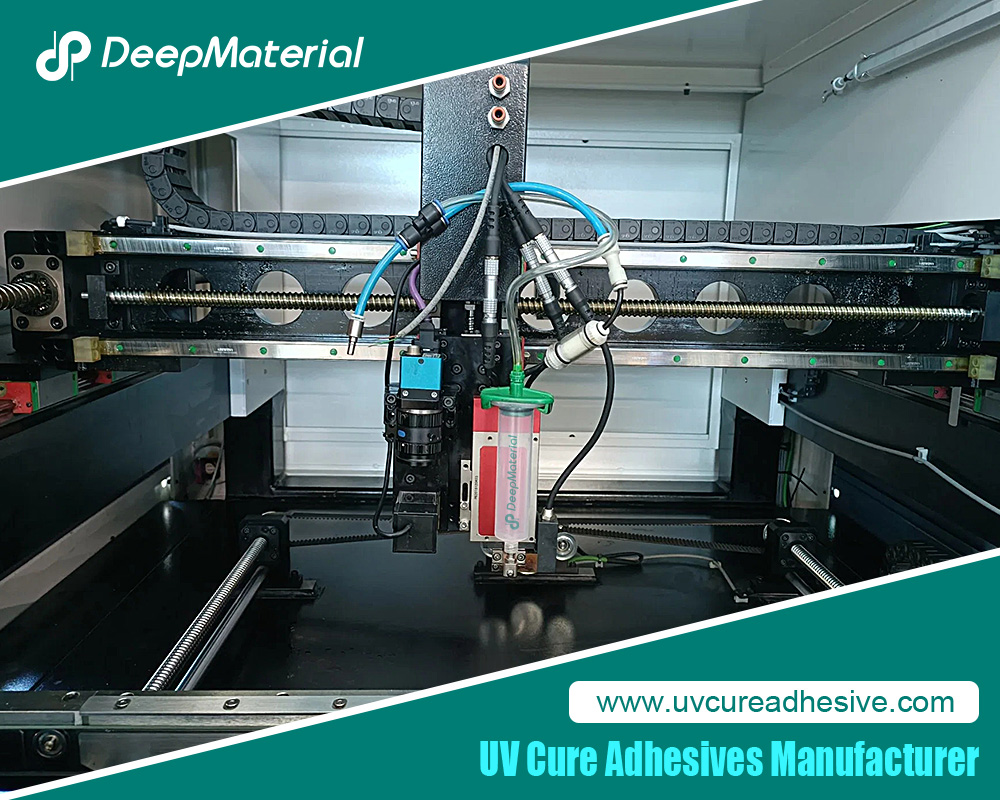

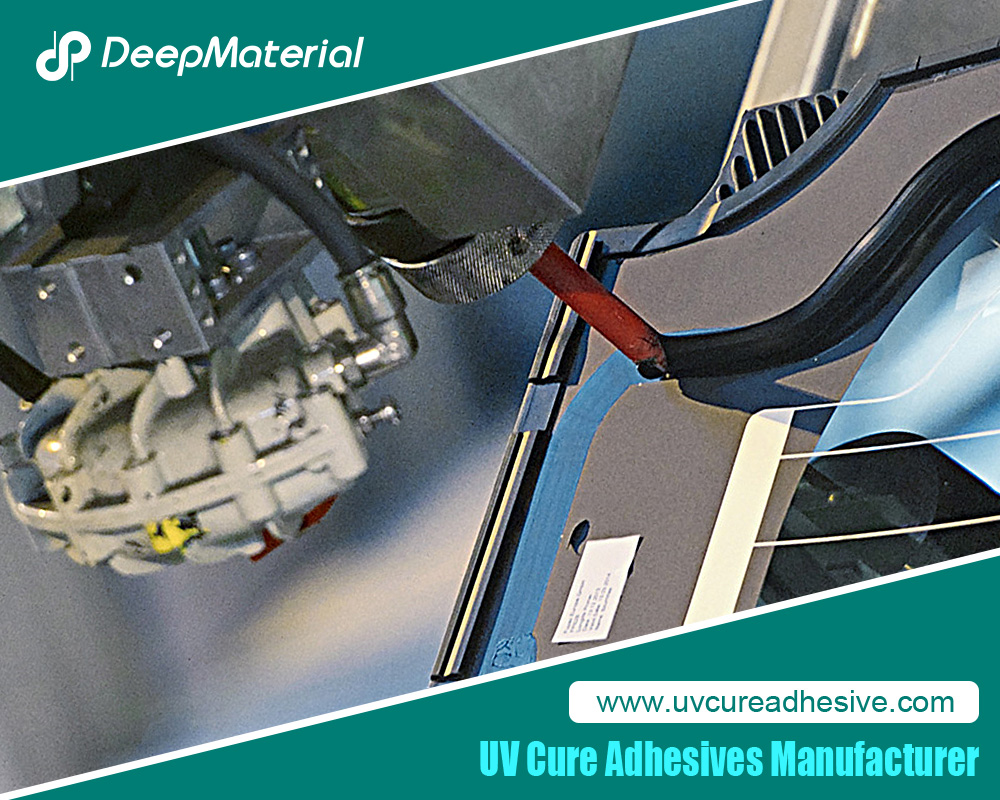

- Increased Use of Robotics and Automation: The application of conformal coatings is becoming increasingly automated with robotics and precision machinery. This trend is helping to reduce application costs and improve the consistency and quality of coatings.

- Integration of Coatings with Smart Technologies: There is a growing trend towards integrating conformal coatings with intelligent technologies, such as self-healing and self-cleaning coatings. These advanced coatings can repair minor damages or repel contaminants, further enhancing the protection of automotive electronics.

- Expansion into New Markets: While the automotive industry remains a crucial market for conformal coatings, manufacturers are exploring new applications in aerospace, consumer electronics, and medical devices. This diversification is expected to drive further growth in the conformal coatings market.

Regional Analysis

The conformal coatings market for automotive electronics varies significantly across regions, influenced by factors such as automotive production, regulatory environments, and technological advancements. This section provides an overview of the fundamental market dynamics.

North America

North America is a significant market for conformal coatings in automotive electronics, driven by the presence of leading automotive manufacturers and technological advancements in the region. The adoption of electric vehicles and ADAS technologies is robust in North America, fueling the demand for high-performance conformal coatings. Additionally, stringent environmental regulations push manufacturers to adopt environmentally friendly coatings, further boosting market growth.

Europe

Europe is another crucial market for conformal coatings, strongly emphasizing automotive safety and environmental sustainability. The region has several leading automotive manufacturers at the forefront of developing advanced electronic systems. The European Union’s stringent regulations on vehicle emissions and safety standards drive the adoption of conformal coatings, particularly in electric and hybrid vehicles.

Asia-Pacific

The Asia-Pacific region is expected to witness significant growth in the conformal coatings market for automotive electronics, driven by the rapid expansion of the automotive industry in countries such as China, Japan, and South Korea. The region is a central hub for automotive manufacturing, with a strong focus on innovation and technological advancements. The growing demand for electric vehicles in Asia-Pacific also contributes to the increased adoption of conformal coatings.

Latin America, the Middle East & Africa

The conformal coatings market in Latin America, the Middle East, and Africa is relatively smaller compared to other regions but is expected to grow steadily. The expansion of the automotive industry in these regions, along with increasing investments in infrastructure and manufacturing, is driving the demand for conformal coatings. However, economic instability and lack of awareness may hinder market growth in these regions.

Future Prospects

The future of the conformal coatings market for automotive electronics looks promising, with several factors expected to drive continued growth. These include the ongoing advancements in automotive electronics, the increasing adoption of electric and autonomous vehicles, and the development of new and innovative coatings. However, challenges such as high costs and environmental concerns will need to be addressed to realize this market’s full potential.

Technological Innovations

One key area of focus for the future will be the development of new conformal coating technologies that offer enhanced protection while being cost-effective and environmentally friendly. Innovations such as self-healing coatings, nanocoatings, and smart coatings are expected to play a significant role in the conformal coatings market’s future.

Expansion into Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, offer significant growth opportunities for conformal coatings. As the automotive industry continues to expand in these regions, the demand for advanced electronic systems and the need for adequate protection through conformal coatings are expected to increase.

Collaboration and Partnerships

Collaboration between automotive manufacturers, coating suppliers, and research institutions will be crucial in driving innovation and addressing the challenges of the conformal coatings market. Partnerships focused on developing new materials, improving application processes, and reducing environmental impacts will be critical to this market’s future success.

Conclusion

The conformal coatings market for automotive electronics is poised for significant growth, driven by electronic systems’ increasing complexity and importance in modern vehicles. While challenges such as high costs and environmental concerns exist, the ongoing advancements in coating technologies and the expanding automotive industry offer promising opportunities for the future. As the automotive industry continues to evolve, conformal coatings will play an increasingly vital role in ensuring the reliability, durability, and performance of automotive electronics.

For more about choosing a conformal coatings market for automotive electronics: an in-depth analysis, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.