UV Curing Optical Adhesive: Revolutionizing Modern Bonding Solutions

In the rapidly advancing field of materials science, UV-curing optical adhesives have emerged as a groundbreaking solution for various applications. These adhesives, which cure upon exposure to ultraviolet (UV) light, offer numerous advantages over traditional adhesives, including faster curing times, enhanced bonding strength, and greater precision. This article delves into the intricacies of UV-curing optical adhesives, exploring their properties, applications, advantages, and prospects of this innovative technology.

Understanding UV Curing Optical Adhesives

UV-curing optical adhesives are specialized bonding agents designed to heal or harden when exposed to UV light. Unlike conventional adhesives that rely on chemical reactions over time or exposure to air, UV-curing adhesives undergo a rapid photochemical response initiated by UV light. This process produces a quick and durable bond, making these adhesives ideal for high-precision applications in various industries.

Composition and Properties

The primary components of UV-curing optical adhesives include photoinitiators, monomers, oligomers, and various additives. Photoinitiators are crucial as they absorb UV light and initiate the curing process. Monomers and oligomers form the adhesive matrix, providing the necessary mechanical properties, while additives enhance specific characteristics such as flexibility, adhesion, and thermal stability.

Critical properties of UV-curing optical adhesives include:

- Rapid Curing:UV adhesives can cure in seconds to minutes, significantly reducing production time.

- High Transparency:These adhesives are often optically clear, making them suitable for minimal light distortion applications.

- Strong Adhesion:They bond robustly to various substrates, including glass, plastic, and metals.

- Low Shrinkage:Minimal shrinkage during curing ensures precision and stability in bonded assemblies.

- Chemical Resistance:UV adhesives resist solvents, moisture, and other environmental factors.

Applications of UV Curing Optical Adhesives

The versatility of UV-curing optical adhesives makes them suitable for a wide range of applications across different industries. Some of the key application areas include:

Electronics and Optoelectronics

In the electronics industry, UV-curing optical adhesives are used to assemble and seal components such as LCD displays, touch screens, and camera modules. Their ability to bond delicate components without causing thermal damage is precious in manufacturing high-precision electronic devices.

Medical Devices

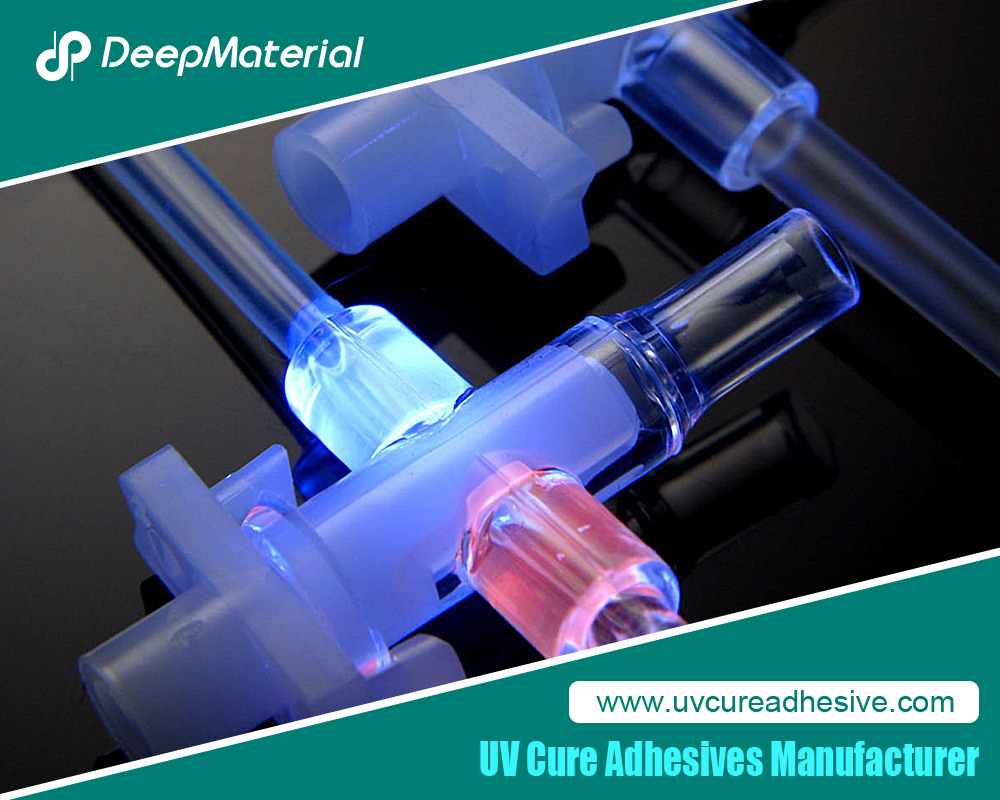

UV adhesives are crucial in the medical device industry, where biocompatibility and precision are paramount. They are used to assemble catheters, syringes, and various diagnostic devices. The rapid curing process ensures that medical devices can be manufactured quickly and accurately.

Automotive and Aerospace

In the automotive and aerospace sectors, UV-curing optical adhesives are used for bonding and sealing applications that require high strength and durability. These adhesives help assemble lightweight components, enhance fuel efficiency, and ensure the reliability of critical parts such as sensors and cameras.

Optical and Photonics Industry

UV-curing optical adhesives are extensively used in the optical and photonics industry for bonding lenses, prisms, and other optical components. Their high transparency and low shrinkage ensure minimal optical distortion, making them ideal for cameras, microscopes, and laser systems applications.

Consumer Goods

UV-curing optical adhesives are integral in assembling various consumer goods, from smartphones to wearables. Their ability to bond different materials quickly and effectively makes them indispensable in the fast-paced consumer electronics market.

Advantages of UV Curing Optical Adhesives

The widespread adoption of UV-curing optical adhesives can be attributed to their numerous advantages over traditional adhesives and bonding methods.

Speed and Efficiency

One of the most significant advantages of UV-curing adhesives is their rapid curing time. Unlike conventional adhesives, which may take hours or even days to cure, UV adhesives can harden within seconds to minutes when exposed to UV light. This speed enhances production efficiency and reduces downtime in manufacturing processes.

Precision and Control

UV-curing optical adhesives provide excellent control over the curing process. Manufacturers can precisely control the curing area by directing UV light only where needed, reducing waste and ensuring high precision in assembly. This is particularly beneficial in applications requiring fine detail and intricate bonding.

Enhanced Bond Strength

The photochemical curing process results in strong, durable bonds that can withstand various environmental conditions, including temperature fluctuations, humidity, and chemical exposure. This reliability is crucial for applications in demanding industries such as aerospace, automotive, and medical devices.

Versatility

UV-curing optical adhesives can bond with various substrates, including glass, plastics, metals, and ceramics. This versatility makes them suitable for diverse applications across different industries. Additionally, these adhesives can be formulated to meet specific requirements, such as flexibility, rigidity, or thermal stability.

Environmental Benefits

UV curing adhesives are often solvent-free, reducing the emission of volatile organic compounds (VOCs) during the curing process. This makes them a more environmentally friendly option compared to traditional solvent-based adhesives. Furthermore, the fast curing times contribute to energy savings in manufacturing processes.

Future Prospects and Innovations

UV-curing optical adhesives are continuously evolving, driven by materials science and technological advancements. Several emerging trends and innovations are poised to shape the future of this technology.

Advanced Photoinitiators

Research is ongoing to develop more efficient photoinitiators to initiate curing with lower-energy UV light. This advancement would enable UV curing adhesives in applications where high-intensity UV light is impractical or potentially damaging.

Hybrid Adhesives

Hybrid adhesives that combine UV curing with other curing mechanisms, such as heat or moisture, are gaining attention. These adhesives offer enhanced performance and flexibility, making them suitable for applications with complex bonding requirements.

Nanotechnology Integration

Nanotechnology is being explored to enhance the properties of UV-curing optical adhesives. Incorporating nanoparticles can improve adhesion, mechanical strength, and thermal stability. Additionally, nanotechnology can enable the development of adhesives with unique optical properties, expanding their application potential.

Bio-based UV Adhesives

As sustainability becomes a growing concern, there is increasing interest in developing bio-based UV-curing adhesives. These adhesives are derived from renewable sources and offer an environmentally friendly alternative to traditional petrochemical-based adhesives.

3D Printing and Additive Manufacturing

UV-curing adhesives are crucial in advancing 3D printing and additive manufacturing. These adhesives enable the rapid prototyping and production of complex structures with high precision and strength. Innovations in this area are expected to enhance the capabilities of 3D printing technologies further.

Challenges and Considerations

While UV-curing optical adhesives offer numerous advantages, there are also challenges and considerations to keep in mind when using them.

UV Light Penetration

The curing process relies on the penetration of UV light through the adhesive. Ensuring adequate UV light penetration in applications involving thick or opaque materials can be challenging. Manufacturers need to consider the design and thickness of the bonded materials to achieve optimal curing.

Equipment and Safety

UV curing requires specialized equipment, such as UV lamps or LED systems, to emit the necessary UV light. Ensuring the safety of operators and preventing exposure to harmful UV radiation is crucial. Proper shielding and safety measures should be implemented in manufacturing environments.

Material Compatibility

While UV-curing optical adhesives are versatile, not all materials are compatible with UV curing. Some substrates may not allow sufficient UV light penetration or react adversely to UV exposure. Testing and selecting the appropriate adhesive formulation for specific materials is essential.

Long-term Stability

Ensuring UV-cured bonds’ long-term stability and durability is critical, especially in demanding applications. Factors such as temperature variations, humidity, and chemical exposure can affect the adhesive’s performance over time. Thorough testing and quality control are necessary to ensure reliability.

Conclusion

UV-curing optical adhesives have revolutionized bonding solutions across various industries, offering unparalleled speed, precision, and versatility. Their rapid curing times, strong adhesion properties, and environmental benefits make them a preferred choice for high-precision electronics, medical devices, automotive, and more applications.

As technology advances, innovations in photoinitiators, hybrid adhesives, nanotechnology, and bio-based materials are expected to enhance the capabilities and applications of UV-curing optical adhesives further. While challenges exist, their benefits far outweigh the limitations, making them a crucial component in the future of materials science and manufacturing.

In a world where precision, efficiency, and sustainability are increasingly important, UV-curing optical adhesives stand out as a beacon of innovation, driving progress and enabling new possibilities in bonding solutions.

For more about choosing UV curing optical adhesive: revolutionizing modern bonding solutions, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.