Unveiling the Brilliance of UV Glass Adhesive: Revolutionizing Bonding Technology

The quest for the perfect adhesive solution has been ongoing in the intricate world of modern manufacturing and design. Among the plethora of options available, UV glass adhesive has emerged as a game-changer, revolutionizing the way glass is bonded. Its remarkable properties and versatile applications have positioned it at the forefront of bonding technology, catering to industries ranging from automotive to electronics and construction to medical.

Introduction to UV Glass Adhesive

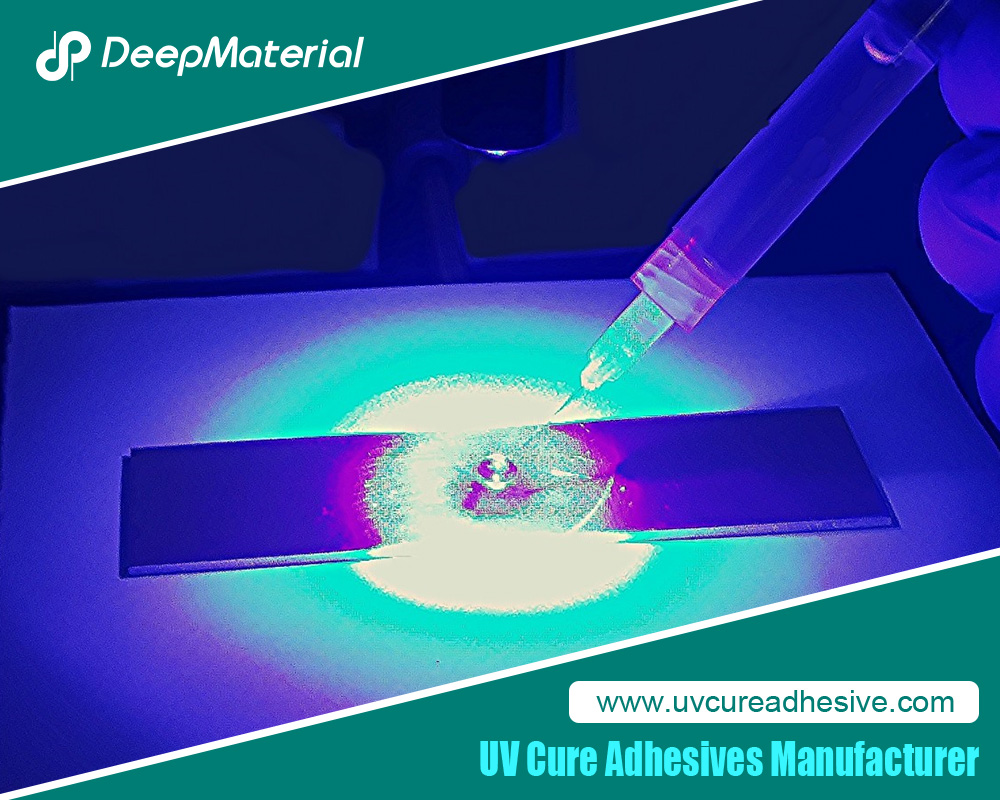

UV glass adhesive, short for ultraviolet glass adhesive, is a type of adhesive that cures or hardens when exposed to ultraviolet (UV) light. This adhesive is composed of monomers, oligomers, photoinitiators, and other additives. When the adhesive is exposed to UV light, a photochemical reaction occurs, leading to the rapid polymerization and hardening of the adhesive, creating a solid and durable bond.

The Chemistry Behind UV Glass Adhesive

Understanding the chemistry behind UV glass adhesive is fundamental to appreciating its efficacy. The key components of UV adhesive include:

- Monomers: These are the building blocks of the adhesive, providing flexibility and adhesion properties.

- Oligomers: These serve as binders, linking the monomers together to form a polymer network.

- Photoinitiators: These compounds absorb UV light and initiate the polymerization process by generating free radicals.

- Additives: Various additives, such as stabilizers, plasticizers, and colorants, may be included to enhance the adhesive’s specific properties.

When exposed to UV light, the photoinitiators absorb the light energy and undergo a photolysis reaction, breaking down into free radicals. These free radicals initiate the polymerization of the monomers and oligomers, forming a crosslinked polymer network. This network rapidly solidifies, creating a solid bond between the bonded surfaces.

Advantages of UV Glass Adhesive

The widespread adoption of UV glass adhesive can be attributed to its numerous advantages:

- Rapid Curing: UV adhesive cures within seconds upon exposure to UV light, significantly reducing assembly time and increasing productivity.

- High Strength: The cured adhesive forms solid, durable bonds capable of withstanding considerable mechanical stress.

- Versatility: UV glass adhesive can bond a wide range of materials, including glass, metals, plastics, and ceramics, making it suitable for diverse applications.

- Transparency: Unlike traditional adhesives that may leave visible residues or bonds, UV glass adhesive provides a clear and transparent bond, maintaining the aesthetic appeal of glass surfaces.

- Chemical Resistance: The cured adhesive exhibits excellent resistance to chemicals, moisture, and temperature fluctuations, ensuring the long-term stability of bonded assemblies.

- Precision: UV adhesive can be applied in very thin layers with high precision, minimizing excess adhesive and optimizing bond strength.

Applications of UV Glass Adhesive

The versatility and performance of UV glass adhesive have led to its widespread adoption across various industries:

- Electronics: UV adhesive is used in the electronics industry to bond glass substrates in displays, touch panels, and optical devices. Its transparent nature and high precision make it ideal for delicate electronic components.

- Automotive: UV adhesive is used in automotive manufacturing to bond glass windows, sunroofs, and headlights. Its rapid curing properties enable efficient assembly line processes while ensuring reliable bonds in critical automotive components.

- Medical Devices: Medical device manufacturers utilize UV adhesive for bonding glass components in instruments, diagnostic devices, and surgical equipment. UV adhesive’s biocompatibility and chemical resistance make it suitable for medical applications.

- Construction: UV adhesive is employed in the construction industry to bond glass panels, facades, and architectural elements. Its transparency and weather resistance contribute to modern architectural designs’ structural integrity and aesthetics.

- Optics: UV adhesive plays a crucial role in assembling lenses, prisms, and optical filters in the optics industry. The optical clarity and precision bonding provided by UV adhesive are essential for achieving high-quality optical systems.

Challenges and Considerations

While UV glass adhesive offers numerous advantages, certain challenges and considerations should be taken into account:

- UV Exposure: Proper UV adhesive curing requires adequate UV light exposure. Complex geometries or shadowed areas may hinder complete curing, necessitating careful design and application.

- Substrate Compatibility: Compatibility between the adhesive and substrate materials is crucial for achieving solid bonds. Surface preparation and compatibility testing are essential to ensure optimal bond performance.

- UV Intensity and Wavelength: The intensity and wavelength of UV light can impact the curing process and bond strength. UV intensity meters and calibrated curing equipment are used to optimize curing conditions.

- Safety Precautions: UV light can pose risks to health and safety if proper precautions are not taken. Personal protective equipment (PPE) and safety protocols should be followed to minimize exposure to UV radiation.

Future Perspectives

The future of UV glass adhesive is brimming with possibilities. Ongoing research and development efforts are focused on enhancing UV adhesives’ performance, versatility, and sustainability. Advancements in photoinitiator technology, formulation chemistry, and curing equipment are expected to further expand the applications and efficacy of UV adhesives in diverse industries.

Additionally, the growing demand for environmentally friendly and sustainable bonding solutions is driving innovation in UV adhesive formulations. Bio-based monomers, recyclable materials, and energy-efficient curing processes are being explored to reduce the environmental footprint of UV adhesive manufacturing and usage.

Overcoming Challenges and Innovations in UV Glass Adhesive

Addressing UV Exposure Challenges

One of the primary challenges associated with UV glass adhesive is ensuring uniform UV exposure, especially in complex or shadowed areas. Manufacturers are addressing this challenge through innovative solutions such as:

- Advanced Curing Equipment: Developments in UV curing equipment, including multi-directional UV lamps and light guides, help ensure uniform exposure and curing even in challenging geometries.

- Adaptive Formulations: Optimized for low-intensity UV curing or extended exposure times, these formulations allow for more flexibility in curing conditions, improving bond quality in difficult-to-reach areas.

Enhancing Substrate Compatibility

The compatibility between UV adhesive and substrate materials is critical for achieving solid and durable bonds. To enhance substrate compatibility, manufacturers are exploring:

- Surface Modification Techniques: Pre-treatment methods such as plasma treatment, corona discharge, or surface priming improve substrate wettability and adhesion.

- Adhesion Promoters: Incorporating adhesion promoters or coupling agents in UV adhesive formulations enhances bonding between dissimilar materials, expanding the range of compatible substrates.

Optimizing UV Intensity and Wavelength

The intensity and wavelength of UV light significantly influence the curing process and bond strength of UV glass adhesive. Innovations aimed at optimizing UV intensity and wavelength include:

- UV Intensity Monitoring Systems: Real-time UV intensity monitoring systems ensure consistent curing conditions throughout the bonding process, enhancing bond quality and reliability.

- UV LED Technology: Advancements in UV LED technology offer precise control over UV wavelength and intensity, allowing for tailored curing profiles and improved bond performance.

Ensuring Safety and Compliance

Safety remains paramount when working with UV glass adhesive due to the potential risks associated with UV radiation exposure. Manufacturers are implementing stringent safety measures and compliance standards, including:

- Safety Interlocks: UV curing equipment has safety interlocks and fail-safe mechanisms to prevent accidental exposure and ensure operator safety.

- Regulatory Compliance: To ensure workplace safety and regulatory compliance, as well as adherence to international safety standards and regulations, such as those set forth by organizations like the Occupational Safety and Health Administration (OSHA) and the International Electrotechnical Commission (IEC).

The Path Ahead: Opportunities and Challenges

As UV glass adhesive continues to evolve, several opportunities and challenges lie ahead:

- Sustainability: The demand for sustainable bonding solutions drives research into bio-based monomers, recyclable materials, and energy-efficient curing processes. Embracing sustainability initiatives will be crucial for the long-term viability of UV adhesive technology.

- Miniaturization and Microelectronics: With the trend toward miniaturization in electronics and the rise of microelectronics, there is a growing need for UV adhesives capable of bonding ultra-thin substrates and delicate components with high precision.

- Emerging Applications: Emerging technologies such as flexible displays, wearable electronics, and photovoltaics present new opportunities for UV glass adhesives. Adapting UV adhesive formulations to meet the unique requirements of these applications will be vital to unlocking their full potential.

Despite these opportunities, challenges such as substrate compatibility, process optimization, and safety considerations will continue to shape the evolution of UV glass adhesive technology. Collaboration between researchers, manufacturers, and end-users will be essential to overcome these challenges and drive innovation in the field of UV adhesive bonding.

Conclusion

The journey of UV glass adhesive from a niche bonding solution to a ubiquitous technology has been marked by innovation, perseverance, and collaboration. Its remarkable properties, including rapid curing, high strength, and versatility, have made it indispensable across various industries. As the demand for faster, more robust, and more sustainable bonding solutions continues to grow, UV glass adhesive stands poised to meet the challenges of tomorrow, driving progress and innovation in manufacturing, design, and technology. With ongoing advancements and a commitment to excellence, UV glass adhesive will continue to shape the future of bonding technology for years to come.

For more about unveiling the brilliance of UV glass adhesive: revolutionizing bonding technology, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.