Understanding UV Light Curing Adhesives: Technology, Applications, and Benefits

Ultraviolet (UV) light-curing adhesives are a pivotal innovation in adhesives and bonding technologies. These adhesives utilize UV light to initiate a polymerization process, resulting in rapid curing and strong bonding. This article explores the technology behind UV light-curing adhesives, their diverse applications, and the benefits they offer in various industries.

What Are UV Light Curing Adhesives?

UV light-curing adhesives are adhesives that cure or harden upon exposure to ultraviolet light. Unlike traditional adhesives that rely on air or chemical reactions to set, UV-curing adhesives use UV light to trigger a chemical reaction that rapidly transforms the adhesive from a liquid to a solid. This process involves the following key components:

- Monomers and Oligomers: These are the building blocks of the adhesive. Monomers are small molecules that can join to form polymers, while oligomers are short chains of monomers. Both are crucial in UV curing as they determine the adhesive’s final properties.

- Photoinitiators: These compounds absorb UV light and initiate the polymerization reaction. When exposed to UV light, photoinitiators decompose into reactive species that start the polymerization of the monomers and oligomers.

- Additives: Various additives enhance the performance of the adhesive. These can consist of stabilizers, colorants, or fillers to adjust the adhesive’s properties, such as viscosity, adhesion strength, or flexibility.

How UV Light Curing Adhesives Work

The curing process of UV light-curing adhesives involves several steps:

- Application: The adhesive is applied to the surfaces to be bonded. At this stage, the adhesive is liquid and can flow into small crevices and cover large areas.

- Exposure to UV Light: Once the adhesive is applied, it is exposed to UV light. The UV light is typically emitted from specialized lamps or LEDs that emit wavelengths in the UV spectrum. The light activates the photoinitiators in the adhesive.

- Polymerization: The photoinitiators generate reactive species when exposed to UV light, which then initiates the polymerization of the monomers and oligomers. This reaction rapidly converts the liquid adhesive into a solid, forming a strong bond between the surfaces.

- Curing Time: The process is usually very fast, often taking seconds to minutes, depending on the adhesive formulation and UV light intensity. This rapid curing allows for quick processing and turnaround times in manufacturing.

Applications of UV Light Curing Adhesives

UV light-curing adhesives have applications in various industries due to their unique properties. Some notable applications include:

Electronics

In the electronics industry, UV light-curing adhesives are used for various purposes, including:

- Bonding Components: Adhesives bond electronic components such as circuit boards, sensors, and connectors. Their quick curing time reduces production time and increases efficiency.

- Encapsulation: UV adhesives encapsulate electronic components, protecting them from moisture, dust, and mechanical damage.

Automotive

The automotive industry utilizes UV-curing adhesives for:

- Interior Trim: Adhesives bond interior trim pieces, ensuring a solid, durable bond that can withstand vibrations and temperature changes.

- Exterior Parts: UV-curing adhesives bond exterior components, such as mirrors and trim, where fast curing and durability are essential.

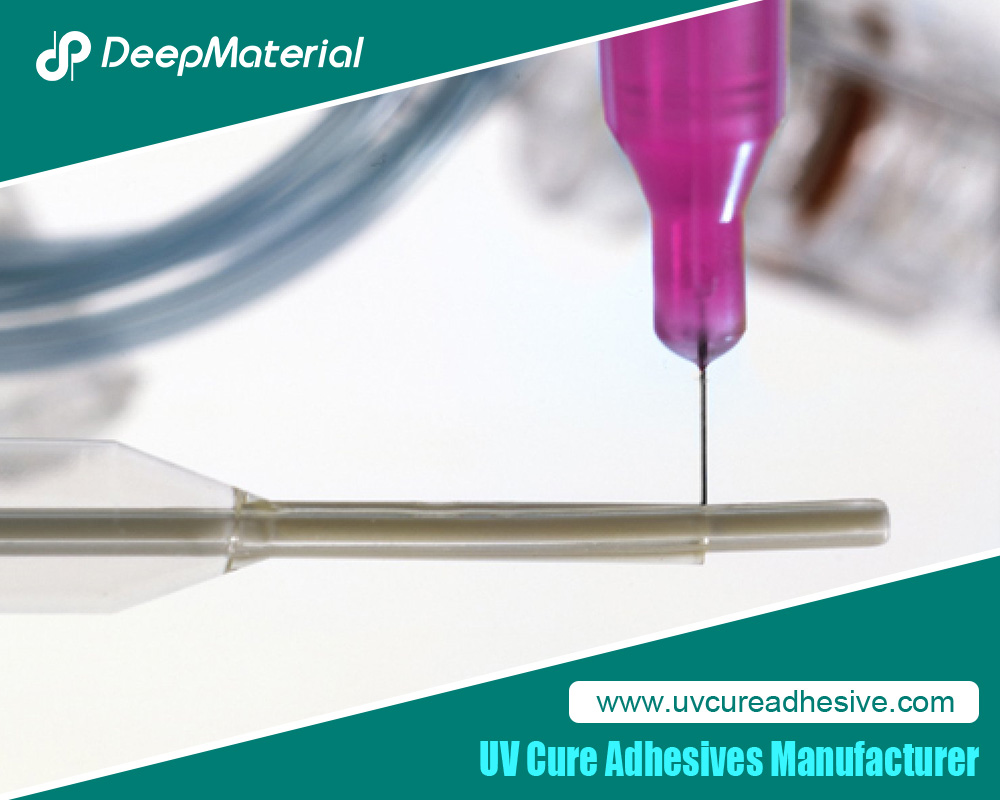

Medical Devices

In the medical field, UV-curing adhesives are employed in the:

- Medical Device Assembly: Adhesives assemble medical devices and instruments where precision and reliability are critical.

- Catheters and Tubing: UV adhesives provide a secure bond for medical tubing and catheters, ensuring their reliability in medical applications.

Optics

UV light curing adhesives are used in optics for:

- Lens Bonding: They bond optical lenses and other components in optical devices, where clarity and precision are crucial.

- Optical Assemblies: UV curing adhesives provide an evident, durable bond for complex optical assemblies used in cameras, microscopes, and other optical instruments.

Packaging

In the packaging industry, UV-curing adhesives are utilized for:

- Labeling: Adhesives are used for labeling packaging materials, where fast curing helps maintain high-speed production lines.

- Box Assembly: UV curing adhesives assemble cardboard boxes and other packaging materials, ensuring a strong and secure bond.

Benefits of UV Light Curing Adhesives

The use of UV light-curing adhesives offers several advantages over traditional adhesive technologies:

Fast Curing Time

One of the most significant benefits of UV-curing adhesives is their rapid curing time. Unlike traditional adhesives that can take hours or even days to set, UV-curing adhesives can achieve a solid bond in seconds to minutes. This fast curing speeds up production processes and reduces manufacturing time.

High Bond Strength

UV-curing adhesives typically provide high bond strength, making them suitable for applications that require a durable and reliable bond. The polymerization process creates a solid cross-linked network of polymers, resulting in a robust adhesive that can withstand various stresses.

Precision and Control

Adjusting the intensity and duration of UV light exposure can precisely control the curing process of UV adhesives. This allows for fine-tuning the adhesive’s properties and ensures consistent results.

Low-Temperature Processing

UV-curing adhesives can be cured at relatively low temperatures, which is advantageous for heat-sensitive substrates and components. This low-temperature processing helps to avoid warping or damage to sensitive materials.

Environmental Considerations

UV-curing adhesives are often more environmentally friendly than traditional adhesives. They typically contain fewer volatile organic compounds (VOCs), reducing the impact on air quality and contributing to a safer working environment.

Reduced Need for Solvents

Many UV-curing adhesives are solvent-free, eliminating the need for additional solvent handling and disposal. This reduces the overall environmental footprint and improves safety in manufacturing environments.

Enhanced Durability

The final cured adhesive is often highly resistant to environmental factors such as moisture, UV light, and chemicals. This enhances the durability and longevity of the bonded materials, making UV-curing adhesives suitable for demanding applications.

Challenges and Considerations

While UV light-curing adhesives offer numerous benefits, there are some challenges and considerations to keep in mind:

Equipment Costs

The initial investment in UV curing equipment, such as UV lamps or LEDs, can be relatively high. However, the increased efficiency and reduced production time often offset this cost.

Surface Preparation

Surfaces must be clean and properly prepared for optimal bonding. Contaminants or uneven surfaces can affect the adhesive’s performance and bond strength.

UV Light Penetration

The effectiveness of UV-curing adhesives depends on the ability of UV light to penetrate the adhesive layer. Obtaining complete curing may be challenging for thick adhesives or opaque substrates.

Health and Safety

UV light exposure can pose health risks if proper precautions are not taken. Adequate protective measures, such as shielding and personal protective equipment, are necessary to handle UV light-curing systems safely.

Future Trends and Innovations

The field of UV light-curing adhesives continues to evolve with advancements in technology and materials. Some emerging trends and innovations include:

Improved Formulations

Researchers are developing new formulations that enhance the performance of UV-curing adhesives, such as improved adhesion to a broader range of substrates and enhanced resistance to environmental factors.

Enhanced UV Light Sources

Advances in UV light sources, such as more efficient UV LEDs and improved curing systems, are increasing UV curing processes’ effectiveness and energy efficiency.

Smart Adhesives

Developing innovative adhesives that respond to environmental changes or external stimuli is an active research area. These adhesives could offer enhanced functionality and performance in various applications.

Sustainable Solutions

Efforts are underway to develop more sustainable UV-curing adhesives that reduce environmental impact and improve recyclability. This includes reducing or eliminating the use of harmful chemicals and solvents.

Conclusion

UV light-curing adhesives represent a significant advancement in adhesive technology, offering fast curing times, high bond strength, and numerous applications across various industries. Their ability to rapidly bond materials with precision and control makes them a valuable tool in modern manufacturing and assembly processes. As technology evolves, UV light-curing adhesives are expected to play an increasingly important role in innovative applications and sustainable solutions.

For more about understanding UV light curing adhesives: technology, applications, and benefits, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.