Understanding UV Hardening Adhesives: Applications, Benefits, and Future Trends

UV-hardening adhesives stand out in modern adhesives due to their unique properties and applications in modern adhesives. These adhesives, also known as UV-curable adhesives, offer rapid curing times and exceptional bonding strength, making them ideal for various industries. This article will delve into the mechanisms of UV hardening adhesives, their applications across different sectors, benefits, and emerging trends in this innovative field.

1. What Are UV Hardening Adhesives?

UV-hardening adhesives are adhesives that cure and harden upon exposure to ultraviolet (UV) light. These adhesives contain photo-initiators, chemicals that absorb UV light and initiate a polymerization process. This process transforms the liquid adhesive into a solid, durable bond.

1.1. Mechanism of UV Curing

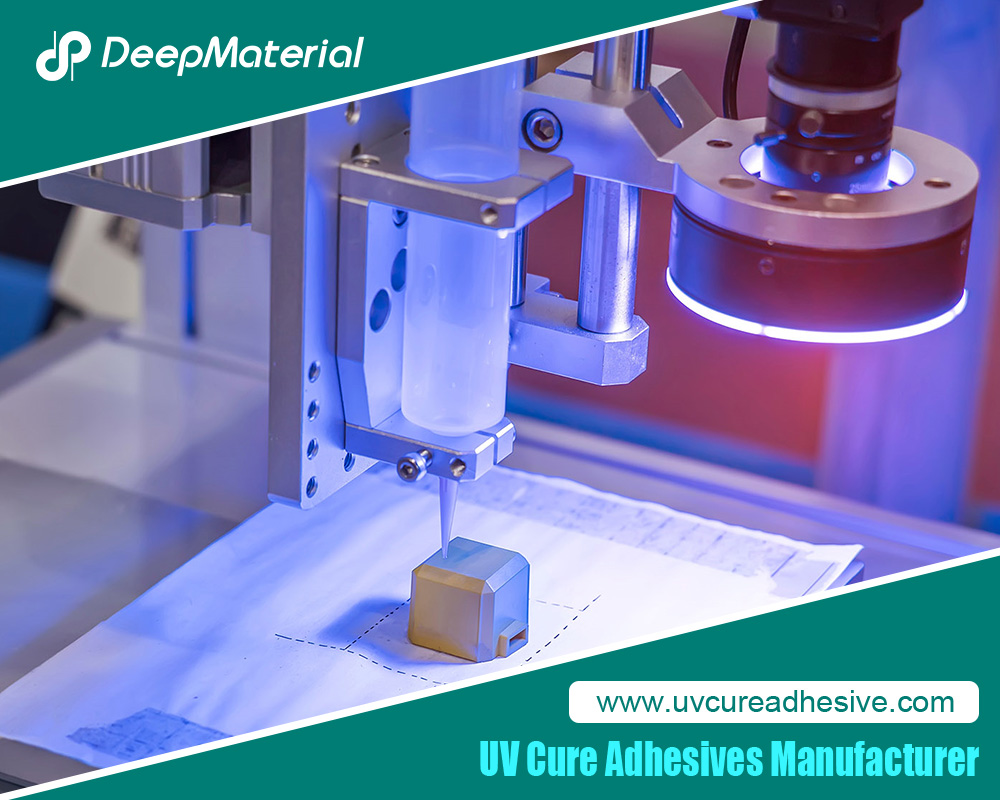

The curing process begins when the adhesive is exposed to UV light, typically emitted by a UV lamp or LED light source. The photo-initiators in the adhesive absorb the UV light and become activated, forming free radicals. These free radicals then react with the adhesive’s monomers, causing them to link and create a polymer network. This polymerization process hardens the adhesive quickly, usually within seconds to minutes.

1.2. Types of UV Hardening Adhesives

UV hardening adhesives can be categorized based on their chemical composition and the type of UV light required for curing. Common types include:

- Acrylic-Based UV Adhesives: Known for their strong bonding capabilities and resistance to environmental factors.

- Epoxy-Based UV Adhesives: Offer excellent mechanical properties and chemical resistance.

- Silicone-Based UV Adhesives: Provide flexibility and are resistant to extreme temperatures.

2. Applications of UV Hardening Adhesives

UV hardening adhesives are used in various applications across various industries due to their versatility and efficiency. Here are some key sectors where these adhesives are particularly valuable:

2.1. Electronics Industry

In the electronics industry, UV-hardening adhesives are used for:

- Component Assembly: Bonding components to circuit boards with precision and minimal thermal stress.

- Protective Coatings: Applying coatings to electronic devices to enhance durability and resistance to environmental factors.

2.2. Automotive Industry

The automotive industry benefits from UV adhesives in several ways:

- Interior Assembly: Adhesives are used to attach trim and other interior components.

- Exterior Bonding: UV adhesives bond exterior parts like headlights and mirrors, offering durability and weather resistance.

2.3. Medical Device Manufacturing

In medical device manufacturing, UV hardening adhesives are crucial for:

- Device Assembly: Ensuring strong bonds in delicate medical instruments and devices.

- Wound Care: Providing secure and sterile adhesive solutions for wound dressings.

2.4. Optical Applications

In optical applications, UV adhesives are used for:

- Lens Bonding: Joining lenses to frames or other optical components with high clarity and precision.

- Display Assembly: Assembling displays in electronic devices with minimal distortion.

2.5. Packaging Industry

The packaging industry uses UV adhesives for:

- Labeling: Applying labels to various surfaces with solid adhesion and resistance to environmental factors.

- Container Sealing: Ensuring secure seals on packaging to maintain product integrity.

3. Benefits of UV Hardening Adhesives

UV hardening adhesives offer numerous advantages over traditional adhesive systems. Some of the key benefits include:

3.1. Rapid Curing Time

One of the most significant advantages of UV adhesives is their rapid curing time. Unlike conventional adhesives that may require hours or even days to cure fully, UV adhesives can harden in seconds to minutes. This speed enhances production efficiency and reduces manufacturing time.

3.2. Precise Control

UV curing allows for precise control over the bonding process. Manufacturers can adjust the UV light exposure to control the curing time and location. This precision is particularly beneficial in applications requiring exact alignment and bonding.

3.3. High Bond Strength

UV hardening adhesives typically offer high bond strength, making them suitable for applications requiring strong and durable bonds. They adhere well to various substrates, including plastics, metals, and glass.

3.4. Minimal Heat Generation

Since UV curing is a cold process, it generates minimal heat during bonding. This feature is advantageous for heat-sensitive materials and components, preventing deformation or damage.

3.5. Environmental Considerations

UV adhesives are often considered environmentally friendly because they do not release volatile organic compounds (VOCs) during curing. This makes them a better choice for industries seeking to reduce their environmental impact.

4. Challenges and Considerations

Despite their advantages, UV-hardening adhesives also present specific challenges and considerations:

4.1. UV Light Penetration

The effectiveness of UV curing depends on the ability of UV light to penetrate the adhesive and reach the photo-initiators. Achieving complete curing may be challenging in applications involving thick or opaque materials.

4.2. Equipment Costs

The initial investment in UV curing equipment can be significant. Businesses must weigh this cost against the benefits of faster curing times and improved adhesive performance.

4.3. Safety Precautions

Exposure to UV light can be harmful to the skin and eyes. Proper safety measures and protective equipment are necessary to ensure the safety of operators working with UV curing systems.

4.4. Limited Shelf Life

Some UV adhesives have a limited shelf life due to their sensitivity to light. Proper storage and handling are essential to maintaining their effectiveness.

5. Future Trends in UV Hardening Adhesives

The field of UV hardening adhesives is continually evolving, with several emerging trends shaping the future of this technology:

5.1. Advancements in UV Light Sources

The development of more efficient and versatile UV light sources, such as LEDs with varying wavelengths, is expanding the range of applications for UV adhesives. These advancements improve curing efficiency and allow for greater flexibility in adhesive formulation.

5.2. Innovations in Adhesive Formulations

Researchers are continually developing new formulations of UV-hardening adhesives with enhanced properties, such as increased flexibility, improved adhesion to challenging substrates, and more excellent resistance to environmental factors.

5.3. Integration with Automation

As automation becomes more prevalent in manufacturing, UV hardening adhesives are increasingly integrated into automated processes. This integration streamlines production, enhances precision, and reduces manual labor.

5.4. Environmentally Friendly Formulations

A growing focus is on developing environmentally friendly UV adhesives with reduced environmental impact. Innovations in formulations aim to minimize the use of harmful chemicals and improve the sustainability of adhesive products.

5.5. Expansion into New Industries

UV hardening adhesives are finding new applications in emerging industries such as renewable energy and advanced materials. As technology progresses, their versatility is likely to drive their adoption in new and innovative fields.

Conclusion

UV hardening adhesives represent a significant advancement in adhesive technology, offering rapid curing times, high bond strength, and precise control. Their applications span various industries, from electronics and automotive to medical devices and packaging. While challenges exist, ongoing research and technological advancements are driving the future of UV adhesives, leading to innovations in formulation, equipment, and environmental considerations. As these trends evolve, UV-hardening adhesives are poised to play an increasingly important role in modern manufacturing and beyond.

For more about understanding UV hardening adhesives: applications, benefits, and future trends, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.