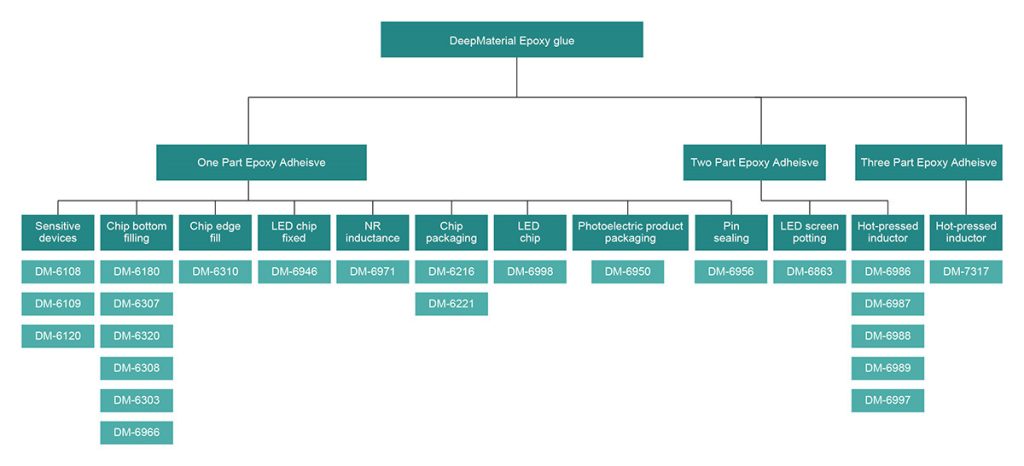

Two Part Epoxy Adhesive

DeepMaterial Two Part Epoxy Adhesive

DeepMaterial’s Two Part Epoxy Adhesive is consists of two separate components: a resin and a hardener. These components are typically stored in separate containers and are mixed together in a specific ratio just prior to use, a chemical reaction is initiated, leading to the curing and hardening of the adhesive, causing it to cross-link and form a strong, durable bond.

Advantages Two Part Epoxy Adhesive

Versatility: They can bond a wide range of materials, including metals, plastics, ceramics, composites, and even dissimilar materials.

High bond strength: The adhesive provide excellent bonding strength and can create durable bonds with high shear, tensile, and peel strengths.

Adjustable cure time: The cure time of a two-part epoxy adhesive can be adjusted by varying the mixing ratio or using different curing agents. This allows for flexibility in different applications, where a shorter or longer working time may be required.

Temperature resistance: These adhesives often exhibit good resistance to high temperatures, making them suitable for applications where the bonded joint may be exposed to elevated temperatures.

Chemical resistance: Two Part Epoxy Adhesives typically offer resistance to chemicals, solvents, and environmental factors, making them suitable for use in harsh or corrosive environments.

Gap filling: They have the ability to fill gaps and bond irregular or uneven surfaces, providing a strong and reliable bond even in situations where the mating surfaces are not perfectly matched.

Two Part Epoxy Adhesive Applications

Two Part Epoxy Adhesives are widely used in various industries, including automotive, aerospace, electronics, construction, and general manufacturing. They find applications in bonding, sealing, potting, encapsulating, and repairing a wide range of components and structures.

Some common uses include:

Automotive industry: These adhesives are extensively used in automotive manufacturing and repair for bonding metal and plastic components, such as body panels, trim pieces, brackets, and interior parts. They provide high-strength bonding, vibration resistance, and durability.

Aerospace industry: Two Part Epoxy Adhesives are widely employed in the aerospace sector for bonding composite materials, such as carbon fiber reinforced polymers (CFRP) and fiberglass, in the construction of aircraft structures. They are used in applications such as bonding panels, attaching brackets, and joining composite parts.

Electronics industry: These adhesives are used for potting, encapsulation, and bonding of electronic components. They provide insulation, protection against moisture and contaminants, and mechanical stability for components on printed circuit boards (PCBs), semiconductor devices, and electronic assemblies.

Construction industry: The Adhesive find applications in construction for structural bonding, anchoring, and repair of concrete, stone, wood, and other building materials. They are used in applications like bonding floor tiles, repairing cracks, and securing anchors.

Marine industry: These adhesives are commonly used in the marine sector for bonding fiberglass, composites, and various materials used in boat and ship construction. They provide resistance to water, chemicals, and marine environments, making them suitable for bonding hulls, decks, and other marine components.

Metal fabrication: Two Part Epoxy Adhesives are employed in metal fabrication and manufacturing for bonding metal parts, joining dissimilar metals, and securing inserts or fasteners. They provide high-strength bonding and can withstand mechanical stress and temperature variations.

General manufacturing: These adhesives find applications in various manufacturing processes, including the bonding of plastics, composites, ceramics, and other materials. They are used for assembly, bonding of components, and structural bonding in industries such as appliances, furniture, sporting goods, and more.

Arts and crafts: These adhesives are popular in arts and crafts projects due to their strong bonding capabilities and versatility. They can be used for bonding different materials like wood, plastic, glass, and metals in jewelry making, model building, and other creative applications.

DeepMaterial adheres to the research and development concept of “market first, close to the scene”, and provides customers with comprehensive products, application support, process analysis and customized formulas to meet customers’ high-efficiency, low-cost and environmental protection requirements.

Two Part Epoxy Adhesive Product Selection

| Product Seriess | Product name | Product typical application |

| Hot-pressed inductor | DM-6986 | A two-component epoxy adhesive, specially designed for the integrated induction cold pressing process, has high strength,excellent electrical performance and strong versatility. |

| DM-6987 | A two-component epoxy adhesive specially designed for the integrated induction cold pressing process. The product has high strength, good granulation characteristics and high powder yield. | |

| DM-6988 | A two-component high-solid epoxy adhesive, specially designed for the integrated induction cold pressing process, has high strength, excellent electrical performance and strong versatility. | |

| DM-6989 | A two-component epoxy adhesive specially designed for the integrated induction cold pressing process. The product has high strength, excellent cracking resistance and good aging resistance. | |

| DM-6997 | A two-component epoxy adhesive specially designed for the integrated induction hot-pressing process. The product has good demoulding performance and strong versatility. | |

| LED screen potting | DM-6863 | A two-component transparent epoxy adhesive used for the manufacture of LED splicing screen in GOB packaging process.The product has fast gel speed, low curing shrinkage, less aging yellowing,high hardness and friction resistance. |

Product Data Sheet of Two Part Epoxy Adhesive