The Future of Electronics: Bonding with UV Cure Adhesive

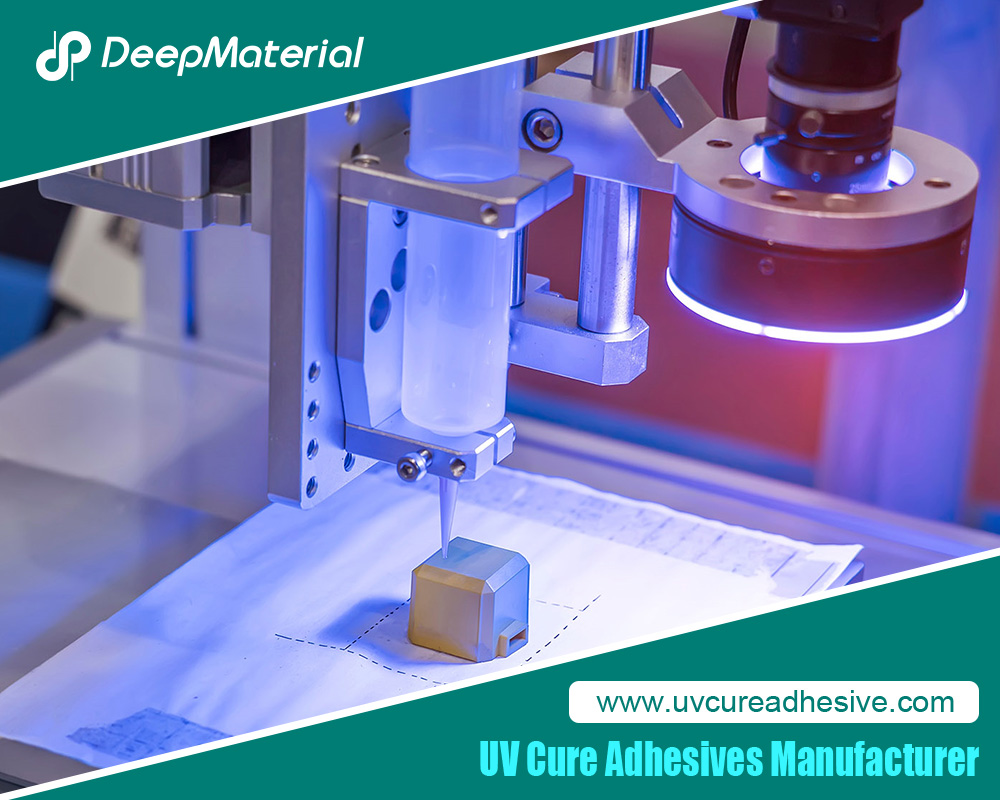

Adhesive bonding is key in electronics. It helps stick parts together and keeps electronic devices working well. UV cure adhesive, a kind of glue that sets fast under ultraviolet light, has become really popular for its special features and benefits.

Advantages of UV Cure Adhesive in Electronics

A big plus of UV cure adhesive in electronics is it sets really fast. Other glues take hours or days to dry, but UV cure adhesive dries in seconds or minutes under UV light. This makes making electronics faster and more efficient.

UV cure adhesive also makes a stronger bond than other glues. When it cures, it makes a really strong and lasting connection between parts. This strong bond means electronic devices can last longer and work better, even when they’re used a lot or in tough conditions.

This adhesive also helps make electronics more reliable. It keeps parts from moving or coming apart, which means less chance of the device breaking or not working right. This is especially good for devices used in places with lots of movement, bumps, or changes in temperature.

Plus, UV cure adhesive is better for the environment. Other glues can let out bad chemicals while they dry, but UV cure adhesive doesn’t use these harmful solvents. So, it’s a safer choice for making electronics that’s also better for the planet.

The Role of UV Cure Adhesive in Miniaturization of Electronics

Making electronic devices smaller has been a big trend. Smaller, lighter, and more portable gadgets are in demand. UV cure adhesive is key to making these tiny electronics. It bonds small parts quickly and strongly, making it possible to create compact devices that work well and fit into tight spaces. This glue is important for making small things like smartphones, tablets, and smartwatches.

UV cure adhesive sticks well to many materials used in electronics, like plastic, glass, metal, and ceramic. This makes it possible to stick different materials together tightly, even as devices get smaller. It also stands up well to extreme temperatures, moisture, and chemicals, which makes miniaturized electronics more reliable and long-lasting.

UV Cure Adhesive for Flexible Electronics

Flexible electronics, like wearable gadgets, bendable screens, and stretchy sensors, are getting a lot of attention. UV cure adhesive is crucial here too. It can stick different types of materials together, even if they bend or stretch differently. This is great for making devices that have both rigid and flexible parts.

This adhesive also sticks really well to flexible materials used in these electronics, ensuring they don’t come apart when bent or stretched. It’s used in making flexible screens and sensors, keeping everything connected and working right.

UV Cure Adhesive for Wearable Electronics

Wearable gadgets, like fitness bands and smartwatches, are more popular than ever. UV cure adhesive is great for these devices because it sticks to many materials they’re made of. It keeps components like sensors and batteries attached tightly, even with lots of movement.

It’s also resistant to moisture and sweat, which is important for gadgets worn on the body. This keeps the insides dry and safe. From fitness bands to smart clothes, UV cure adhesive keeps wearable electronics working well, no matter the conditions.

UV Cure Adhesive for Automotive Electronics

Automotive electronics are very important in cars, helping with safety, comfort, and how well the car runs. UV cure adhesive is really useful for putting electronic parts together in cars because it has a lot of benefits.

A big plus of UV cure adhesive in cars is that it can handle really hot and really cold temperatures. Car electronics have to work in all kinds of weather, from very cold to very hot. This glue keeps its strength even when the temperature changes a lot.

It also stands up well to shaking and stress, which cars often face. The glue can take a lot of force without letting the electronic parts come loose, making sure everything in the car works right.

UV cure adhesive is used in lots of car parts, like control modules, sensors, screens, and lights. It makes sure these parts stay attached to the car, inside and out.

UV Cure Adhesive for Medical Electronics

Medical electronics are very important for health care, helping with diagnosing, monitoring, and treating patients. UV cure adhesive has many advantages for putting together parts in medical devices.

One important benefit for medical electronics is that this glue is safe to use with the human body. Since medical devices often touch the body or even go inside it, the glue has to be non-toxic. UV cure adhesive is made to be safe and not harm patients.

This glue can also handle being sterilized, which is a must for medical tools. It stays strong even after being cleaned with methods like autoclaving or radiation, and it’s resistant to many chemicals and fluids. This means medical devices can be used for a long time without problems.

UV cure adhesive is used in things like health monitors worn on the body, devices put inside the body, and tools for diagnosing diseases. Using this glue makes medical devices safe, reliable, and effective.

UV Cure Adhesive for Aerospace Electronics

Aerospace electronics are very important for planes, helping with talking, finding the way, and controlling the aircraft. UV cure adhesive is really good for putting together electronic parts in planes because it has a lot of benefits.

One big plus of UV cure adhesive in planes is that it can handle really tough conditions. Things like high up in the sky, big changes in pressure, very cold or hot temperatures, and shaking. This glue keeps its strength in all these situations, making sure that the electronic parts in planes work well.

It also sticks very well to different materials used in planes, like metals, special mixes, and ceramics. This means electronic parts can be firmly attached to different places, making sure they work right even when there’s a lot of stress.

UV cure adhesive is used in lots of plane electronics, like avionics systems, antennas, sensors, and lights. It makes sure these parts stay attached to the plane, inside and out.

The Future of Electronics Bonding with UV Cure Adhesive

To wrap up, UV cure adhesive brings a lot of good things to the table for sticking electronic parts together in different fields. Its quick setting time, strong connections, better dependability, and smaller impact on the environment make it a top pick for making electronics.

Looking forward, the use of UV cure adhesive in electronics has a bright road ahead with lots of room for new improvements. Efforts to make it better are ongoing, with the goal to make the adhesive set even quicker, create stronger bonds, and handle tough conditions even better.

As technology gets better, there will be more need for tinier, stronger, and more dependable electronic gadgets. UV cure adhesive is set to be a key player in fulfilling these needs, helping to bring out new electronic products that make our lives better and push forward progress in many areas.

For more about choosing a comprehensive guide to the Future of Electronics: Bonding with UV Cure Adhesive, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.